www.industryemea.com

01

'23

Written on Modified on

Bühler delivers its battery production solutions to Fraunhofer’s new test facility and industrial plant in Germany

German Fraunhofer Research Institution for Battery Cell Production FFB and Swiss technology company Bühler Group are taking their collaboration to new heights. Fraunhofer FFB has been operating Bühler’s technology for continuous mixing of battery slurry since 2021.

Now, Bühler’s 30-millimeter extruder will be used by the teams at its new research and development site in Münster, Germany, where the Fraunhofer-Gesellschaft is building a test facility spanning over 6,000 square meters (FFB PreFab). In parallel, the Fraunhofer-Gesellschaft is also building an industrial plant – called FFB Fab – where Bühler’s 93-millimeter extruder will enable a throughput of up to about 1,200 liters of battery slurry per hour.

The research organization Fraunhofer-Gesellschaft intends to play a leading role in the development of industrial battery production facilities in Europe. The construction of a new test facility at its research and development site in Münster, Germany, and of a gigafactory on the same premises are part of this plan. “The Fraunhofer FFB has a clear goal. We research and develop solutions for scaling production technology for lithium-ion batteries. Our customers are German automakers who want to get into battery production to make themselves less dependent on international suppliers and plant manufacturers in the battery industry,” says Markus Eckstein, the Fraunhofer FFB Research Associate.

Ten kilometers further south from its current pilot plant (FFB Workspace), in the Hansa-Business Park Münster, the complete outer shell of the FFB PreFab, the next milestone of the Fraunhofer FFB, is already in place. The construction should be concluded in 2024 and the existing Bühler 30-millimeter extruder installation will be moved to the FFB PreFab. The pilot installation combines an industry-relevant production capacity with simple operation. “Thanks to its modular design, a very large number of process parameters can be run down within a very short time and thus the mixing process can be efficiently optimized,” explains Philipp Stoessel, Team Manager Process Technology Grinding & Dispersing at Bühler.

At the FFB PreFab, the teams will conduct experimental research with customers and universities in an area of 6,000 square meters. “In our innovation modules, we can take advantage of the shorter changeover and cleaning times. This allows us to improve existing processes, apply new technologies, and extrapolate the knowledge gained to industrial applications,” says Eckstein.

Bühler’s continuous mixing process is unique in the industry. It allows raw material dosing, premixing, kneading, fine dispersing, and degassing in a single device. “Thanks to Bühler’s continuous mixing technology, we can determine accurate parameters for scaling and transfer them to the gigafactory scale. Bühler’s battery experts keep challenging us to look at things in a new way, and we are in active exchange when it comes to new technologies and best practices. For example, we are fascinated by QuaLiB, an in-house development at Bühler, which allows the quality of the electrode slurry to be analyzed in real time and ensures traceability of the process,” explains Eckstein.

Fraunhofer industrial plant

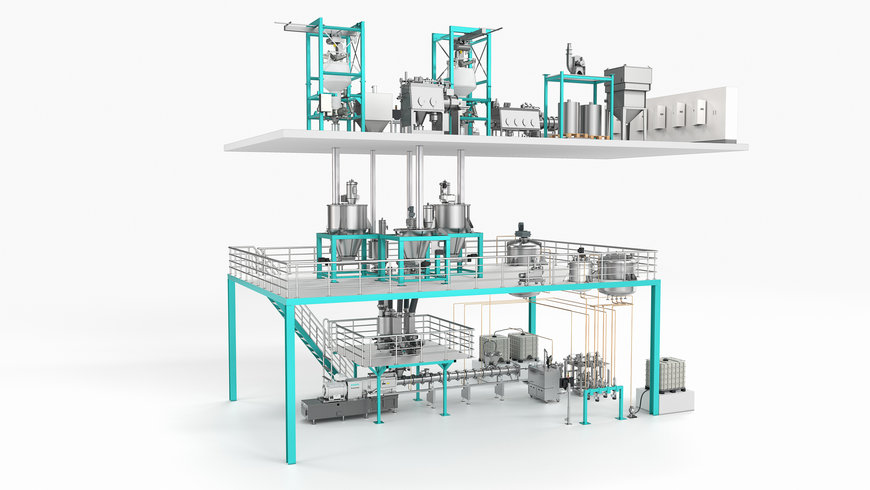

The collaboration doesn’t end there. Bühler also won a public tender and will build a 93-millimeter extruder as well as sophisticated systems for handling, storing, and metering the raw materials, and for slurry storage at Fraunhofer’s industrial plant. The mixing plant will be able to process up to approximately 1,200 liters of electrode slurry per hour.

"It is exceptional to see a research organization building up an entire lithium-ion battery plant in order to perform research at the ton scale. Such industry relevant research will generate precious know-how and might enable the closing of the technology gap between Europe and Asia. Furthermore, it is an ideal platform to build a skilled workforce for the battery industry," says Stoessel. “For Bühler this is a lighthouse project which will help to further promote the fully continuous mixing technology.”

Effervescent market

The Fraunhofer FFB research institution is proof of the dynamic way in which the topic of industrial battery production is moving research and industry. Companies and research institutes are looking for ways to improve capacity, speed charging time, reduce costs, and further drive innovation.

The potential is extensive and Bühler is ready to collaborate with research partners and the automotive industry in building a sustainable future. Bühler set up its Battery Solutions business more than 10 years ago. Based on its proven twin-screw extruder technology for the food and feed industry, Bühler developed a new continuous mixing process for battery slurries. Over these years Bühler has received orders for more than 70 continuous electrode slurry mixing lines worldwide, whereof more than half of it are large-scale production plants.

www.buhlergroup.com