www.industryemea.com

15

'23

Written on Modified on

Siemens Xcelerator: New functions for Sinumerik One increase performance and contribute to a more sustainable production

Sinumerik Ctrl-E in V6.22 with new functions for evaluating and reducing energy consumption. Flexible HMI portfolio for multifunctional machine tools.

With the new Sinumerik software version V6.22, there are new technology functions for the Sinumerik One that increase transparency in the machine, simplify operation, reduce machine wear, and increase performance.

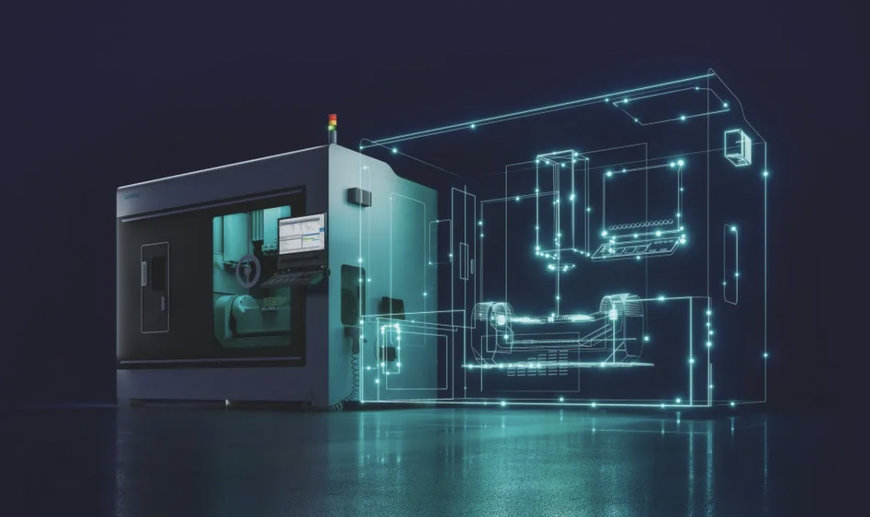

At this year's EMO, Siemens is expanding its range of products and services with the "Digital Native" CNC Sinumerik One. The new CNC generation from Siemens, which was launched on the market in 2019, comes with numerous innovations in software and hardware. With the new Sinumerik software version V6.22, there are new technology functions for the Sinumerik One that increase transparency in the machine, simplify operation, reduce machine wear, and increase performance. This leads to the optimal use of available resources, for example by reducing scrap and repairs. It also helps to increase machine productivity by minimizing idle and production times, for example.

Sinumerik Ctrl-E in V6.22 with new functions

With the simple and well-established Ctrl-E key combination on the control panel, Sinumerik One enables a quick evaluation of the machine's energy consumption. The function enables visualization of the most important energy consumption factors and simple creation as well as management of machine profiles. New in software version V6.22 is the function for optimized spindle acceleration (Balanced Spindle Acceleration). The spindle acceleration is automatically adjusted so that the programmed spindle speed is only reached when required. This reduces the acceleration current and the thermal losses of the spindle motor, which in turn saves electrical energy during spindle operation. This is particularly beneficial when there are many tool changes. In addition, reducing the spindle acceleration to the necessary minimum also reduces the mechanical load, which increases the service life of the spindle.

Flexible HMI portfolio for multifunctional machine tools

Simple and intuitive operation is the top priority for the Sinumerik One HMI portfolio. With the scalable portfolio of 15 to 24 inch multi-touch panels and the matching machine control panels, the requirements of modern multifunctional machine tools for flexibility and adaptability are met. New to the portfolio are the Sinumerik One Machine Control Panels (MCPs) 1900 plus, 1500 and the matching QWERTY keyboards. Not only in hardware, but also in software, the focus is on flexibility and customization. The Sinumerik Operate Display Manager makes it easy to implement a customizable interface that not only adapts to the various display sizes, but also to the individual needs of the machine operator. The Display Manager allows videos and PDFs, for example, to be displayed clearly in various customizable layouts. To meet the ever-increasing performance requirements of the HMI software, the new IPC generations (Simatic IPC 2x7G and Simatic IPC BX/PX-39A) will be used in the future. The additions to the Sinumerik One HMI portfolio guarantee a consistent and scalable hardware concept.

Perfect compatibility in use and programming

Sinumerik One not only offers numerous advantages over its predecessor Sinumerik 840D sl but is also perfectly compatible in use and programming. This not only eliminates the need for retraining for the operator, but also allows programs and cycles to be reused. This saves costs and facilitates the introduction of the new generation of machines.

www.siemens.com

At this year's EMO, Siemens is expanding its range of products and services with the "Digital Native" CNC Sinumerik One. The new CNC generation from Siemens, which was launched on the market in 2019, comes with numerous innovations in software and hardware. With the new Sinumerik software version V6.22, there are new technology functions for the Sinumerik One that increase transparency in the machine, simplify operation, reduce machine wear, and increase performance. This leads to the optimal use of available resources, for example by reducing scrap and repairs. It also helps to increase machine productivity by minimizing idle and production times, for example.

Sinumerik Ctrl-E in V6.22 with new functions

With the simple and well-established Ctrl-E key combination on the control panel, Sinumerik One enables a quick evaluation of the machine's energy consumption. The function enables visualization of the most important energy consumption factors and simple creation as well as management of machine profiles. New in software version V6.22 is the function for optimized spindle acceleration (Balanced Spindle Acceleration). The spindle acceleration is automatically adjusted so that the programmed spindle speed is only reached when required. This reduces the acceleration current and the thermal losses of the spindle motor, which in turn saves electrical energy during spindle operation. This is particularly beneficial when there are many tool changes. In addition, reducing the spindle acceleration to the necessary minimum also reduces the mechanical load, which increases the service life of the spindle.

Flexible HMI portfolio for multifunctional machine tools

Simple and intuitive operation is the top priority for the Sinumerik One HMI portfolio. With the scalable portfolio of 15 to 24 inch multi-touch panels and the matching machine control panels, the requirements of modern multifunctional machine tools for flexibility and adaptability are met. New to the portfolio are the Sinumerik One Machine Control Panels (MCPs) 1900 plus, 1500 and the matching QWERTY keyboards. Not only in hardware, but also in software, the focus is on flexibility and customization. The Sinumerik Operate Display Manager makes it easy to implement a customizable interface that not only adapts to the various display sizes, but also to the individual needs of the machine operator. The Display Manager allows videos and PDFs, for example, to be displayed clearly in various customizable layouts. To meet the ever-increasing performance requirements of the HMI software, the new IPC generations (Simatic IPC 2x7G and Simatic IPC BX/PX-39A) will be used in the future. The additions to the Sinumerik One HMI portfolio guarantee a consistent and scalable hardware concept.

Perfect compatibility in use and programming

Sinumerik One not only offers numerous advantages over its predecessor Sinumerik 840D sl but is also perfectly compatible in use and programming. This not only eliminates the need for retraining for the operator, but also allows programs and cycles to be reused. This saves costs and facilitates the introduction of the new generation of machines.

www.siemens.com