www.industryemea.com

20

'23

Written on Modified on

THE WORLD’S FIRST ZERO CO2 EMISSION TIRE FACTORY SHOWS THE WAY WITH A HOLISTIC APPROACH TO SUSTAINABILITY

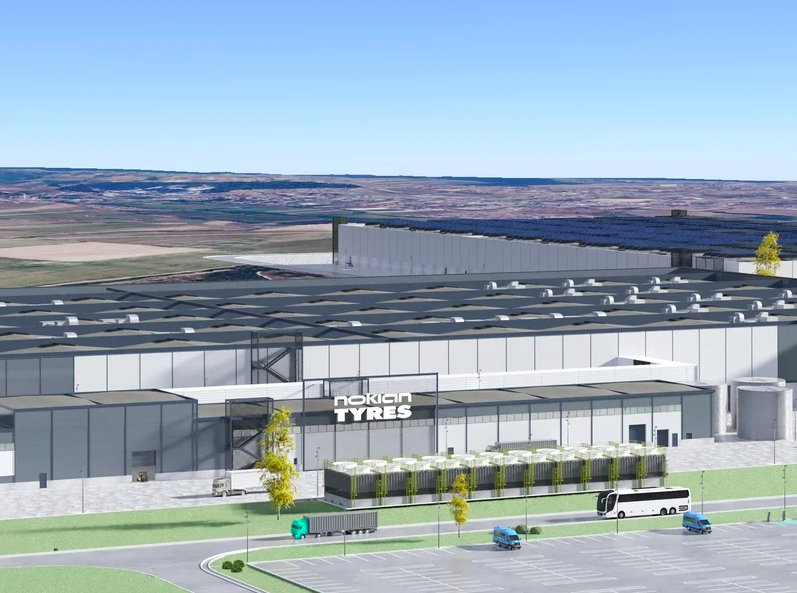

The new Nokian Tyres Oradea factory in Romania will be the world’s first zero CO2 emission tire factory – and so much more in terms of sustainability.

From the very first shovel push to ensuring that the new employees are breathing clean air, the Nokian Tyres Oradea factory will be a complete work of state-of-the-art sustainable solutions.

Leading the way

Carbon dioxide emissions are the primary driver of global climate change and reducing them is key in fighting against the rising global temperatures. Alongside this, a growing number of consumers demand sustainability from the products and services they purchase, including tires. The first-ever zero CO2 emission tire factory sets a standard for future tire production.

Nokian Tyres is starting the race for zero CO2 emissions from a leading position.

"We already produce tires with the lowest factory CO2 emission level in the tire industry. Our CO2 emissions in 2022 were around 400 kilograms per ton of tires manufactured, whereas the majority of our competitors operate between 800 and 1100 kilograms. And the Oradea factory will take us on a whole new, lower, level of CO2 emissions globally," says Teppo Huovila, Vice President of Quality and Sustainability from Nokian Tyres.

Clean energy, efficient processes and modern technical solutions ensure sustainability of production

If the main source for CO2 emissions is energy, how is it possible to achieve the zero CO2 emission standard at a tire manufacturing facility? The answer is simple: we must use energy that produces zero CO2 emissions, says Huovila.

All energy that we use at the Oradea factory will be from zero CO2 emission sources. It can be for example wind, hydro, biomass or solar energy or a mix of several, Huovila explains.

Also, all processes used at the factory will be designed to be as energy-efficient as possible. The aim is to minimize the ratio of energy used per tire manufactured. The high level of automation and robotics guarantees the efficiency of the processes in general, but it also helps to save energy, materials and all other precious resources.

Modern tire manufacturing machines are designed to be very energy-efficient. The state-of-the-art machines we will be installing in the factory support the aim to use as little energy as possible in all the different phases of the production process, says Huovila.

Managing the indirect effects

The Oradea factory is scheduled to begin producing the first tires in the latter half of 2024, and tires for commercial use in 2025. When it is in full working order, there will be environmental effects beyond CO2 emissions to consider, such as production waste.

We are aiming for the same zero waste-to-landfill standard as we have at our Nokia factory. This means that all waste is recycled or reused. A working tire factory produces over ten types of waste, and we are looking for local recycling partners for them all, so that all the recycling processes will be done as close to the factory as possible, Huovila says.

In addition to waste management, things such as transportation and raw materials for the tires indirectly affect the sustainability of the factory.

All vans we acquire will be electric. We are also building electric chargers and bicycle parks for the employees to encourage them to use low emission ways of transport, Huovila says.

As the Oradea factory will be focusing on manufacturing tires for the Central European markets, the distances to transport the finished products are reasonable which lowers emissions.

We will also maximize the use of railroads for transportation, says Huovila.

All transportation companies as well as other partners will be surveyed and chosen based on their sustainability actions.

Sustainability will be measured and reported

All sustainability aspects of the factory, including the zero CO2 emission standard, will be closely measured and reported by independent organizations.

As a pioneering company in the industry, Nokian Tyres was the first tire company to have its science-based targets for reducing greenhouse gas emissions approved by the Science Based Targets initiative in 2020. All the sustainability aspects of the Oradea factory will support us to reach our targets. Our progress will be reported regularly, Huovila states.

In addition to the Science Based Targets initiative, the company does a yearly sustainability reporting including measuring the CO2 emissions from each factory.

We use the international GHG protocol to measure and report CO2 emissions from all our sites. The same protocol is used universally by all companies to measure greenhouse gases. An independent third party verifies the correctness of our reports annually, Huovila says.

www.nokiantyres.com