www.industryemea.com

28

'23

Written on Modified on

Stellantis Celebrates Opening of Its First Battery Technology Center in Italy

Vertically integrating the capability to develop, test and manufacture battery packs and manage software is a key element of the Stellantis strategy to produce class-leading BEVs with customer-focused performance and lower costs.

Stellantis today celebrated the grand opening of its first Battery Technology Center, at the Mirafiori complex in Turin, Italy.

The €40 million investment to develop this state-of-the-art center enhances Stellantis’ capabilities to design, develop and test battery packs, modules, high-voltage cells and software that will power upcoming Stellantis brand vehicles. The center is the biggest in Italy and among the largest in Europe.

More than 100 employees at the Mirafiori Battery Technology Center, most of them upskilled Stellantis workers, will perform and oversee climatic stress tests, lifespan durability testing, battery management system (BMS) software development and calibration, and tear downs of packs and cells for analysis and benchmarking.

Stellantis is also building a Battery Technology Center for North America, in Windsor, Ontario, Canada, as part of a global battery development and manufacturing network that will include six gigafactories.

“We are in the midst of a once-in-a-lifetime opportunity to redefine mobility, providing smart and sustainable solutions for our customers,” said Ned Curic, Stellantis Chief Engineering and Technology Officer. “Our new Battery Technology Center at Mirafiori brings together the tools and talented people we need to design, test, verify and produce class-leading products that will meet our customers’ needs and accelerate bringing class-leading electric vehicles to customers around the world.”

The opening of the Mirafiori Battery Technology Center reinforces the Stellantis commitment to Italy and its workforce there.

Vertical integration of the key milestones for electric vehicle battery packs – from design, to development and testing, to production – form the heart of the Stellantis strategy to produce class-leading BEVs with customer-focused performance. As detailed in the EV Day 2021 presentation, the Stellantis battery plan includes a dual chemistry strategy to serve all customers, design efficiency in battery cells and modules, and housing and pack assembly, for cost competitiveness.

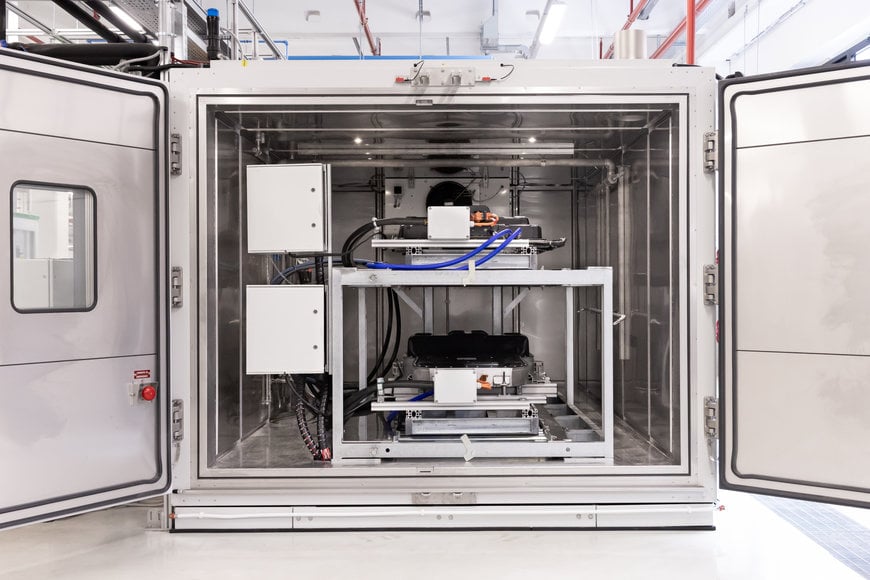

The Mirafiori Battery Technology Center covers 8,000 square meters (86,111 square feet), spread over three levels. The heart of the center is 32 climatic test chambers – 24 walk-in chambers for testing battery packs and eight chambers for testing cells.

The climate in the 24 walk-in chambers can be controlled for humidity and temperature, with a range from -40 to 60 degrees Celsius (-40 to 140 degrees Fahrenheit) and a maximum change of 20 degrees per minute. The center can test up to 47 battery packs in parallel.

Designed for future growth, the technology center’s power system can manage up to 1.2 kilovolts (kV) and 2.2 megawatts (MW) per test cell.

The eight cell chambers are capable of testing 96 cells in parallel. This part of the technology center will be devoted mainly to screening innovative battery chemistry and cell behavior characterization for future development.

As part of the Dare Forward 2030 strategic plan, Stellantis announced plans of reaching a 100% passenger car BEV sales mix in Europe and 50% passenger car and light-duty truck BEV sales mix in the United States by 2030. To achieve these sales targets, the Company is securing approximately 400 GWh of battery capacity, to be supported by six battery manufacturing plants in North America and Europe. Stellantis is on track to become a carbon net zero corporation by 2038, all scopes included, with single-digit percentage compensation of remaining emissions.

www.stellantis.com