www.industryemea.com

15

'24

Written on Modified on

Vishay Intertechnology 30 V N-Channel MOSFET With Source Flip Technology Delivers Best in Class RDS(ON) Down to 0.71 mΩ in PowerPAK® 1212-F

Device Offers High Power Density and Improved Thermal Performance in 3.3 mm x 3.3 mm PowerPAK® 1212 F Package With Center Gate Design.

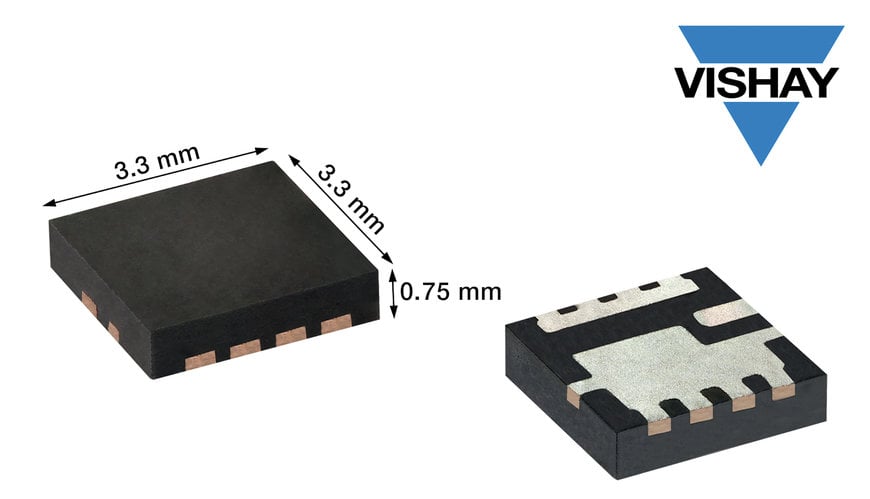

Vishay Intertechnology, Inc, has introduced a versatile new 30 V n-channel TrenchFET® Gen V power MOSFET that delivers increased power density and enhanced thermal performance for industrial, computer, consumer, and telecom applications. Featuring source flip technology in the 3.3 mm by 3.3 mm PowerPAK® 1212-F package, the Vishay Siliconix SiSD5300DN provides best in class on-resistance of 0.71 mΩ at 10 V and on-resistance times gate charge — a critical figure of merit (FOM) for MOSFETs used in switching applications — of 42 mΩ*nC.

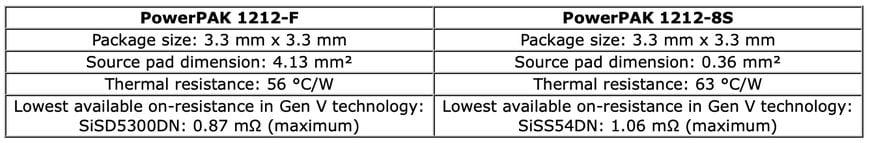

Occupying the same footprint as the PowerPAK 1212-8S, the device released today offers 18 % lower on-resistance to increase power density, while its source flip technology reduces thermal resistance by 63 °C/W to 56 °C/W. In addition, the SiSD5300DN's FOM represents a 35 % improvement over previous-generation devices, which translates into reduced conduction and switching losses to save energy in power conversion applications.

PowerPAK 1212-F source flip technology reverses the usual proportions of the ground and source pads, extending the area of the ground pad to provide a more efficient thermal dissipation path and thus promoting cooler operation. At the same time, the PowerPAK 1212-F minimizes the extent of the switching area, which helps to reduce the impact of trace noise. In the PowerPAK 1212-F package specifically, the source pad dimension increases by a factor of 10, from 0.36 mm² to 4.13 mm², enabling a commensurate improvement in thermal performance. The PowerPAK 1212-F's center gate design also simplifies parallelization of multiple devices on a single-layer PCB.

The source flip PowerPAK 1212-F package of the SiSD5300DN is especially suitable for applications such as secondary rectification, active clamp battery management systems (BMS), buck and BLDC converters, OR-ing FETs, motor drives, and load switches. Typical end products include welding equipment and power tools; servers, edge devices, supercomputers, and tablets; lawnmowers and cleaning robots; and radio base stations.

The device is 100 % RG- and UIS-tested, RoHS-compliant, and halogen-free.

Key Specification Table:

Samples and production quantities of the SiSD5300DN are available now, with lead times of 26 weeks.

www.vishay.com