www.industryemea.com

20

'24

Written on Modified on

ABB PROVIDES THE DRIVING FORCE BEHIND NEXT-GENERATION ELECTRIC PROPULSION FACILITY

A 2 MW dynamometer test stand will support extensive development programs for the electrification of aircraft and other transport at the University of Nottingham.

Using its advanced research facilities, the world-class team at Nottingham aims to develop and test green and sustainable new propulsion systems for all forms of transport, ultimately reducing the sector’s destructive impact on the environment.

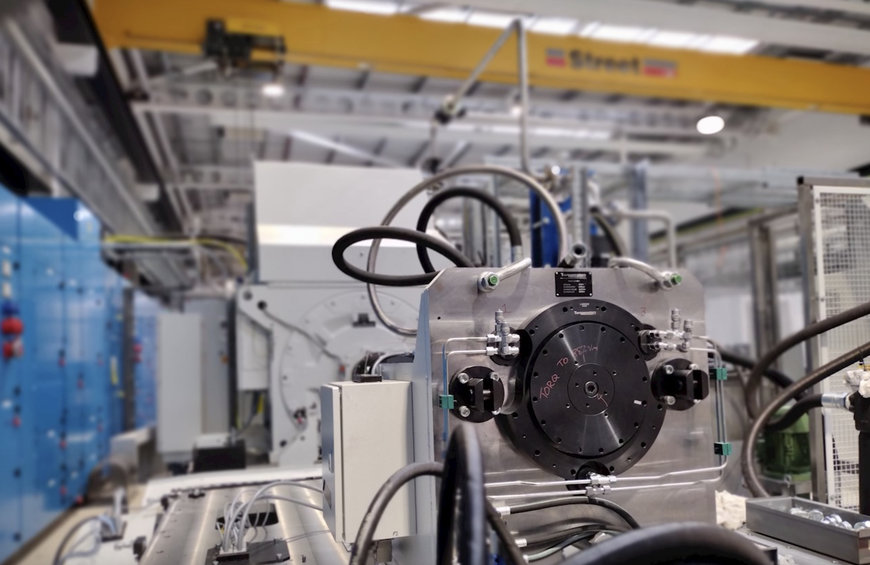

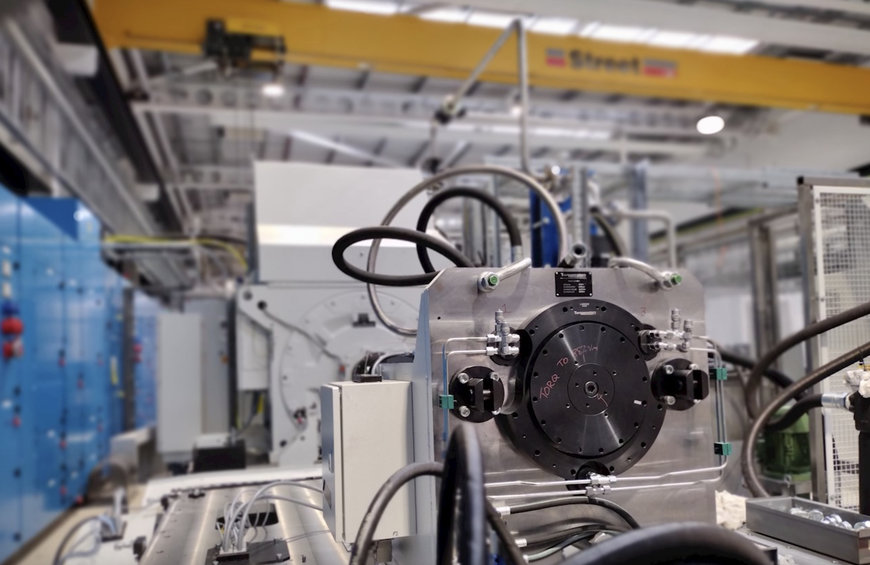

A major new project at the University of Nottingham has seen the installation of an advanced dynamometer test rig at its world-renowned propulsion testing facility. The 2 MW dynamometer, which is an electro-mechanical system with four-quadrant power conversion capability and the ability to dynamically emulate thrust loads, will help open up exciting new possibilities for the future of clean and electrified aviation propulsion systems.

The testing facility is a new addition to the University of Nottingham’s Power Electronics and Machine Centre (PEMC), which is also the home of the Midlands Driving the Electric Revolution Industrialisation Centre (DER-IC). The facility will complement existing MW-class electrical machines and drives design and manufacturing capabilities to enable the whole development cycle of future aircraft propulsion systems under one roof.

Transport is responsible for almost a quarter of global CO2 emissions. Using its advanced research facilities, the world-class team at Nottingham aims to develop and test green and sustainable new propulsion systems for all forms of transport, reducing the sector’s destructive impact on the environment, while benefiting societies across the world. Research is primarily focused on hybrid and electric demonstrators for air, land, and marine transport.

The new test rig is an important step on the path to making the UK an international leader in the development of high-power aerospace electrical systems.

The dynamometer is designed to enable testing and validation of MW- and kV-class electrical drive systems for both low-speed to high-speed (800-30,000rpm) e-motors and generators for hybrid electric propulsion systems. The system can dynamically emulate mechanical loads seen from propellors, gas turbine generators, or any other mechanical transmission. Concurrent torque and thrust can be applied to simulate, for instance, load on a propeller in flight, or the system can be set up to test the output and performance of an engine in representative conditions.

Torquemeters, a specialist engineering company based in Northampton, designed, manufactured, installed, and commissioned the system, which is comprised of an ABB drive and motor, a multiple-output parallel-shaft gearbox, lubrication system, a proprietary in-line phase-shift Torquemeter, high-speed low-mass couplings, and a rig health monitoring system. The system is complemented with a unique controllable and re-configurable power supply system that can emulate different energy sources including batteries, fuel-cells, and APUs.

The ABB drive and motor package solution utilises the company’s advanced ACS880 platform in a liquid-cooled, low-voltage, industrial multi-drive converter format. The converter features an Active Front End (AFE) fully regenerative rectifier, while the drive also includes a separate DC connection cabinet. The cabinet layout was specially designed in an L-shape to fit within the test bay space and accommodate the liquid-cooling unit. The motor was an ABB Optimum Performance modular 2MW 0-75Hz AMI type 560mm frame water-cooled design that was specifically optimised for ACS880 operation. The motor was also designed to operate as a generator.

The 2 MW dynamometer is an electro-mechanical system with four-quadrant power conversion capability, and is used to dynamically emulate thrust loads.

One of the major challenges in designing and building such a system is managing heat dissipation. Traditionally, similar facilities have been built near large bodies of water such as lakes or reservoirs, drawing vast amounts of water in for cooling, while also requiring complex infrastructure to cool the heated water in a closed system. In contrast, Torquemeters’ system uses a regenerative ABB drive, which can absorb excess power and then recirculate it, vastly improving efficiency compared to traditional testing rigs. This significantly lowers the amount of cooling infrastructure required, which in turn reduced the amount of investment required to bring the project to life.

The project was the largest test rig of its kind that Torquemeters had ever built, and thus required a motor and drive of a larger size and rated power than they had previously used. ABB’s solution was chosen in particular for its excellent performance and functionality in larger applications. The regenerative functionality of the drive, and the ability to package both the motor and drive together as a matched pair, were also major benefits.

A major new project at the University of Nottingham has seen the installation of an advanced dynamometer test rig at its world-renowned propulsion testing facility. The 2 MW dynamometer, which is an electro-mechanical system with four-quadrant power conversion capability and the ability to dynamically emulate thrust loads, will help open up exciting new possibilities for the future of clean and electrified aviation propulsion systems.

The testing facility is a new addition to the University of Nottingham’s Power Electronics and Machine Centre (PEMC), which is also the home of the Midlands Driving the Electric Revolution Industrialisation Centre (DER-IC). The facility will complement existing MW-class electrical machines and drives design and manufacturing capabilities to enable the whole development cycle of future aircraft propulsion systems under one roof.

Transport is responsible for almost a quarter of global CO2 emissions. Using its advanced research facilities, the world-class team at Nottingham aims to develop and test green and sustainable new propulsion systems for all forms of transport, reducing the sector’s destructive impact on the environment, while benefiting societies across the world. Research is primarily focused on hybrid and electric demonstrators for air, land, and marine transport.

The new test rig is an important step on the path to making the UK an international leader in the development of high-power aerospace electrical systems.

The dynamometer is designed to enable testing and validation of MW- and kV-class electrical drive systems for both low-speed to high-speed (800-30,000rpm) e-motors and generators for hybrid electric propulsion systems. The system can dynamically emulate mechanical loads seen from propellors, gas turbine generators, or any other mechanical transmission. Concurrent torque and thrust can be applied to simulate, for instance, load on a propeller in flight, or the system can be set up to test the output and performance of an engine in representative conditions.

Torquemeters, a specialist engineering company based in Northampton, designed, manufactured, installed, and commissioned the system, which is comprised of an ABB drive and motor, a multiple-output parallel-shaft gearbox, lubrication system, a proprietary in-line phase-shift Torquemeter, high-speed low-mass couplings, and a rig health monitoring system. The system is complemented with a unique controllable and re-configurable power supply system that can emulate different energy sources including batteries, fuel-cells, and APUs.

The ABB drive and motor package solution utilises the company’s advanced ACS880 platform in a liquid-cooled, low-voltage, industrial multi-drive converter format. The converter features an Active Front End (AFE) fully regenerative rectifier, while the drive also includes a separate DC connection cabinet. The cabinet layout was specially designed in an L-shape to fit within the test bay space and accommodate the liquid-cooling unit. The motor was an ABB Optimum Performance modular 2MW 0-75Hz AMI type 560mm frame water-cooled design that was specifically optimised for ACS880 operation. The motor was also designed to operate as a generator.

The 2 MW dynamometer is an electro-mechanical system with four-quadrant power conversion capability, and is used to dynamically emulate thrust loads.

One of the major challenges in designing and building such a system is managing heat dissipation. Traditionally, similar facilities have been built near large bodies of water such as lakes or reservoirs, drawing vast amounts of water in for cooling, while also requiring complex infrastructure to cool the heated water in a closed system. In contrast, Torquemeters’ system uses a regenerative ABB drive, which can absorb excess power and then recirculate it, vastly improving efficiency compared to traditional testing rigs. This significantly lowers the amount of cooling infrastructure required, which in turn reduced the amount of investment required to bring the project to life.

The project was the largest test rig of its kind that Torquemeters had ever built, and thus required a motor and drive of a larger size and rated power than they had previously used. ABB’s solution was chosen in particular for its excellent performance and functionality in larger applications. The regenerative functionality of the drive, and the ability to package both the motor and drive together as a matched pair, were also major benefits.

www.abb.com