www.industryemea.com

22

'24

Written on Modified on

Dürr develops a new paint supply system for industrial applications

The new EcoSupply P Core is a modular paint supply system based on pigging technology. This paint supply method has already proved beneficial in the automotive painting world, but Dürr has gone one step further and enhanced it for use in other industries for the first time.

The desire for a comprehensive color palette extends beyond the automotive industry. Customers use their color preferences as unique identifiers in other industries, whereas companies use distinctive colors as a unique selling point for themselves and their products. Manufacturers from the construction and plastic industries, for example, require a multitude of available shades to cater to their customers’ needs.

However, each color change in the supply line results in paint and rinsing agent waste during the painting process. This can involve disproportionately high costs, particularly with very small quantities. This is because current paint supply systems clean the hoses using solvent and compressed air to remove all paint and rinsing residues left behind before preparation of the next color run can begin. This process is laborious and time-consuming, with longer and thicker hoses resulting in higher paint losses.

Pigging technology reduces paint consumption

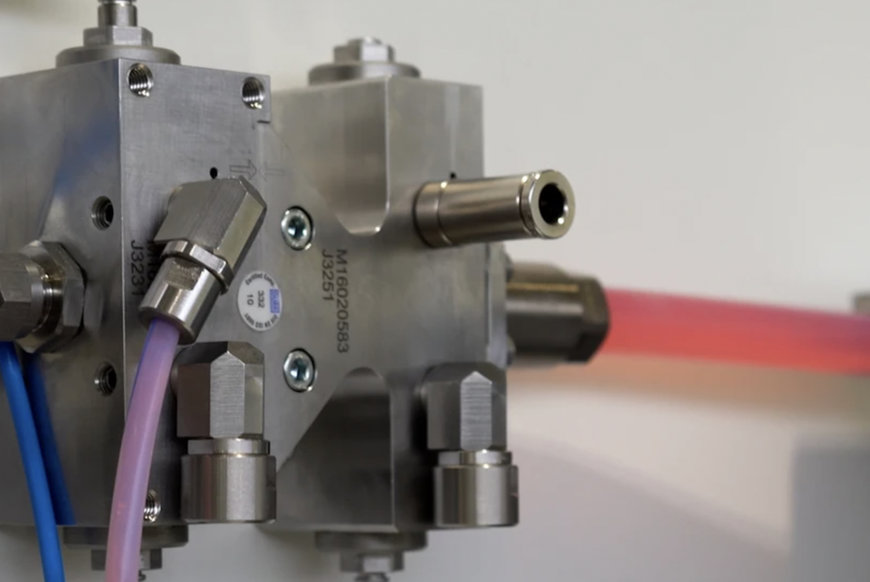

For pigging technology, Dürr uses a fitting body tailored to the internal diameter of the hoses – the so-called pig – to make the process more efficient and reduce paint and rinsing agent consumption. The paint, flowing through the pigging hose, pushes the pig from the source to the target module. This process removes any rinsing agent residue in the hose. Distributor stations, with the option of integrating up to four into one pigging line, provide the connection to the application technology. After the paint application, compressed air blows the pig back towards the source module. In the process, the paint left in the hose is transported back into the paint container. Rinsing agent then flows through the pigging hose towards the destination module. After cleaning, the process repeats.

Faster color changes and simplified maintenance

The EcoSupply P Core comes in single-pass and circulating versions and is suitable for applying both water and solvent-based paints. In both instances, reduced effort makes for faster color changes. Additionally, the modular design simplifies maintenance, allowing flexible configuration of individual components to adapt to user requirements and integrate into existing systems. Thus, the EcoSupply P Core can also integrate with other Dürr systems, such as the EcoSupply2 Core paint supply station.

Starter kit with everything you need

Dürr’s starter kit contains all important components, including a source and destination module, a distributor station for connecting to the application technology, hoses (which come in lengths of up to 100 meters), and the pig itself. The starter kit also includes sensors for monitoring the pig position, maintenance and commissioning tools, and EcoDocu-technical documentation in digital format, complete with system examples.

Twenty-five years of experience in pigging technology

The EcoSupply P Core offers the manufacturing sector a cost-effective, easy-to-use paint supply solution for smaller quantities and applications in the low-pressure range. The new development is the culmination of Dürr’s 25 years of experience with the pigging technology featured in the EcoSupply P. Globally recognized, this tried-and-tested paint supply system with pigging technology has established its effectiveness in automotive painting.

PaintExpo attendees can learn about the new EcoSupply P Core at Dürr’s stand 3320 in hall 3. The sales launch for the EcoSupply P Core is planned for early summer.

www.durr.com