www.industryemea.com

09

'25

Written on Modified on

Bavaria's High-Tech Alliance for the Manufacturing of the Future

As a leading AM equipment supplier and producer and user of AM components, Siemens is contributing its know-how in software and automation to the association.

www.siemens.com

With Bavaria Makes e.V. (in formation), a strong ecosystem for the industrialization of Additive Manufacturing (AM) is being created in Bavaria in Germany. The association, consisting of large companies, medium-sized businesses, universities, research institutions, and the innovation agency of Bavaria with Bayern Innovativ, aims to make Bavaria a globally leading high-tech location for Additive Manufacturing within 10 years.

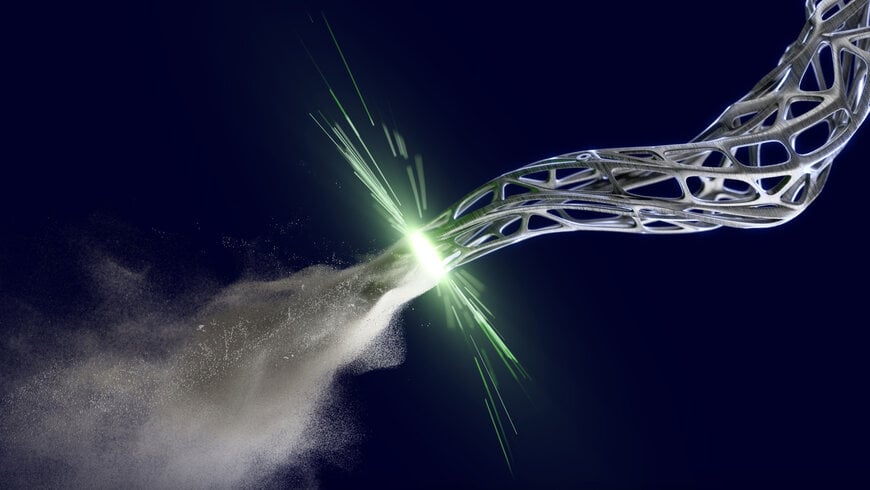

In Additive Manufacturing, components are built up layer by layer and are not produced by material removal like in conventional processes. This enables great flexibility and design freedom, opening up unprecedented possibilities for research and industry. Currently, applications are being developed or already in use for numerous industries such as medical, energy, aerospace & defense, semiconductor, tool making, automotive, and railway industry.

The Bavarian State Government is providing significant funding for the project. A new lighthouse for AM with focus on metallic materials is being created at the Advanced Manufacturing Campus of the Technical University of Munich (TUM) in Garching. Currently, more than 30 professors at the TUM.Additive academic network at TUM are researching the future of Additive Manufacturing together with researchers.

Bavaria's Science Minister Markus Blume emphasizes: "Bavaria is a pioneer in 3D printing. We are excellently positioned in the field of Additive Manufacturing - and we want to get even better, because Additive Manufacturing is a rapidly growing market. Bavaria Makes bundles the know-how from production and research - an alliance of real champions. Following the principle of 'Support, Enhance, Empower', we are further developing the entire ecosystem of Additive Manufacturing in Bavaria and creating efficient structures. As a Ministry of Science, we are contributing five positions and special funds of one million euros to get it started."

These positions form the basis for the relevant subject areas and decisively drive research and industrial implementation in this field. An outstanding example of the close cooperation between science and industry is the TUM-Oerlikon Advanced Manufacturing Institute, which already combines academic and industrial research within the framework of the Industry-on-Campus concept.

Furthermore, the TUM Venture Labs are actively embedded into the campus ecosystem, supporting more than 100 start-ups and entrepreneurial researchers, so-called Sciencepreneuers, in the field of Additive Manufacturing. This joint initiative by TUM and UnternehmerTUM is also partly funded by the Bavarian State Ministry of Science and the Arts.

Bavaria Makes was founded by Bayern Innovativ GmbH, Colibrium Additive, EOS GmbH, MTU Aero Engines AG, Oerlikon AM Europe GmbH, Siemens AG, the Technical University of Munich, and toolcraft AG. The goal is to accelerate the transfer from research to industrial production.

Siemens AG is active in Bavaria both as a leading AM equipment supplier and as a producer and user of AM components for rail technology or medical technology. "We are contributing our know-how in software and automation to the association," says Dr. Karsten Heuser, Vice President Additive Manufacturing at Siemens AG and new member of the Executive Board of Bavaria Makes. "By bundling the forces of Bavarian global companies with universities and SMEs in focused hubs, our customers and we ourselves will become faster and better." Recently, technology experts from Siemens AG have also moved into the campus to advance research activities around hybrid manufacturing processes and production optimization in co-location with TUM.

From October 23 to 24, 2025, Bayern Innovativ will offer an international platform with the "Next Gen Manufacturing" congress to showcase new application potentials of Additive Manufacturing and provide impulses for innovations.