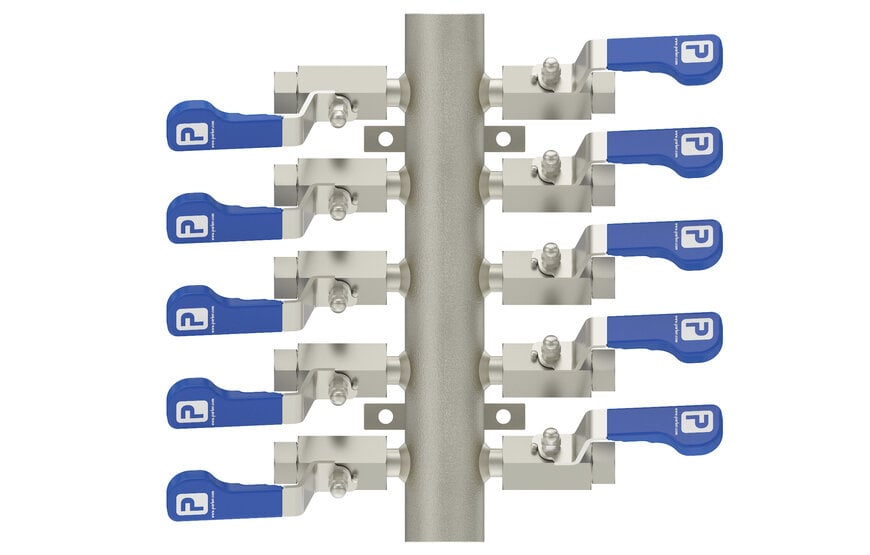

Parker Hannifin Unveils Space-Saving Hi-Pro Manifolds for High-Pressure Industrial Applications

Parker’s compact Hi-Pro manifolds cut size by 40% and weight by 20% for high-pressure oil/gas applications, featuring welded 316 stainless steel construction and leak-resistant A-LOK connections.

www.parker.com

The Instrumentation Products Division Europe of Parker Hannifin, the global leader in motion and control technologies, launches its series of compact Hi-Pro distribution manifolds, designed for industries where space-savings, weight reduction, and high-pressure performance are critical.

Engineered for oil and gas, petrochemical, and chemical applications, the new manifolds are up to 40% shorter and nearly 20% lighter than Parker’s standard Hi-Pro version. The compact design makes the manifolds an ideal choice for offshore platforms, skid-mounted systems, and confined plant areas, where space is at a premium.

“As industrial environments become increasingly space-constrained, engineers need compact solutions that don’t sacrifice performance," said Nick Holton, Product Manager at Parker. “By halving the distance between adjacent outlets, we’ve developed a manifold that optimizes space while maintaining strength and reliability.”

The new design not only reduces footprint but also lowers structural loads, minimizing the need for heavy supports and bracketing. A lighter manifold simplifies handling, reducing installation time and labor costs. With pre-drilled mounting feet, the installation is straightforward, making it easier to integrate into modular and mobile systems.

The compact Hi-Pro distribution manifolds feature a part-welded construction, which significantly reduces the number of connections, minimizing potential leak paths and enhancing safety. All welding is performed by certified professionals to ensure compliance with stringent industry standards.

The manifolds are available with fully integrated A-LOK® tubing connections at the outlets, for improved system integrity and safety. This feature also minimizes potential leak points and streamlines installation.

The product is manufactured from thick-gauge 316 stainless steel that offer exceptional corrosion resistance, preventing internal scaling even in aggressive environments. The innovative domed nut designed by Parker protects threads from moisture and contamination, further reducing corrosion risks. Each manifold undergoes rigorous non-destructive testing (NDT) to ensure performance integrity.

To accommodate a range of application needs, the compact Hi-Pro distribution manifold series supports up to 20 distribution valve outlets and offers both threaded and flanged connection options. Threaded connections handle pressures up to 2,785 psi (192 bar), while flanged connections comply with ASME 150-300 class standards.

Parker also offers a full range of fittings, tubing, and pressure gauges, allowing customers to source all necessary components from a single supplier – reducing procurement time, material costs, and installation complexity.

“A compact manifold doesn’t just save space - it optimizes system layouts, simplifies installation in tight areas, and enhances overall design flexibility,” added Nick Holton. “By offering a complete solution, we help customers streamline operations and lower project costs.”

www.parker.com