www.industryemea.com

09

'17

Written on Modified on

Better and more cost-effective machining with super-duplex stainless steels

Rinaldo Brivio, Global Technical Marketing, Sandvik Materials Technology, explains how operators can strike a balance between optimizing performance in their machining applications while also keeping costs and investments to a low level.

It is known that machining processes are improved by switching from carbon steels to stainless steels, yet operators have found it necessary to slow down machining speeds and alter tool settings after making this change. They also experienced a number of issues such as frequent vibration chatter, gumming of tools and poor chipbreaking.

Such problems did not arise from the switch to stainless steels, but instead from the insufficient quality of the specific chosen replacement material. A solution therefore lies in identifying higher quality stainless steels with proven properties for machining.

Super-duplex stainless steels

It is generally easier to machine carbon steels than super-duplex stainless steels, but the latter have superior mechanical properties. ‘Super-duplex’ grades are so-called because they are more resistant to pitting corrosion than duplex stainless steels.

Sandvik’s own super-duplex stainless steel, Sandvik SAF 2507, has a chemically balanced metallurgy to give it characteristics which are advantageous for machining such as higher mechanical strength, low hardness and ductility. This includes reduced contents of nickel, chromium, molybdenum, carbon and nitrogen and enhanced levels of sulfur, phosphorous and copper.

The material is already used widely in offshore oil and gas exploration and production, in heat exchangers for petrochemical and chemical processing, and is also suitable for hydraulic and instrumentation applications.

Nevertheless, Sandvik wanted to benchmark its own product against an important European steel producer’s competing super-duplex grade. Both materials were subjected to a series of machining tests, in the form of 100 mm diameter bar, at a state-of-the-art Productivity Center and laboratory located in Milan, Italy.

The facility is operated by Sandvik Coromant, a sister company to Sandvik Materials Technology and a global leader in the research, development and supply of tools and services for the metal cutting industry. In 2012, Sandvik Coromant appeared in Forbes magazine’s list of ‘The World’s Most Innovative Companies’ because of its advancements in machining.

Turning tests

The tests at Sandvik Coromant’s facility firstly assessed each super-duplex material’s turning capabilities, when a steel cylindrical workpiece is rotated at high speeds in a machining lathe while a single point cutting tool is moved parallel to the axis of rotation, as shown in Image 1. This process is normally applied to a workpiece externally to reduce its diameter to a specified dimension.

The super-duplex materials were subjected to medium-to-rough machining at a specified insert geometry, with a view to finding the optimized balanced between cutting speed and feed that gives the longest tool life. The workpieces were fed at a rate of 0,3 millimeters per revolution (mm/rev), and subjecting to cutting speeds of between 60 to 125 meters per minutes (m/min) to a depth of between 2 and 3 mm.

Machining was performed until, either: the desired flank wear (of 0,3 mm) was reached; or significant signs of wear were spotted such as edge fracture on the main or secondary cutting edge, plastic deformation, chipping, or notch wear on the cutting edge equal to or greater than 0,5 mm/rev.

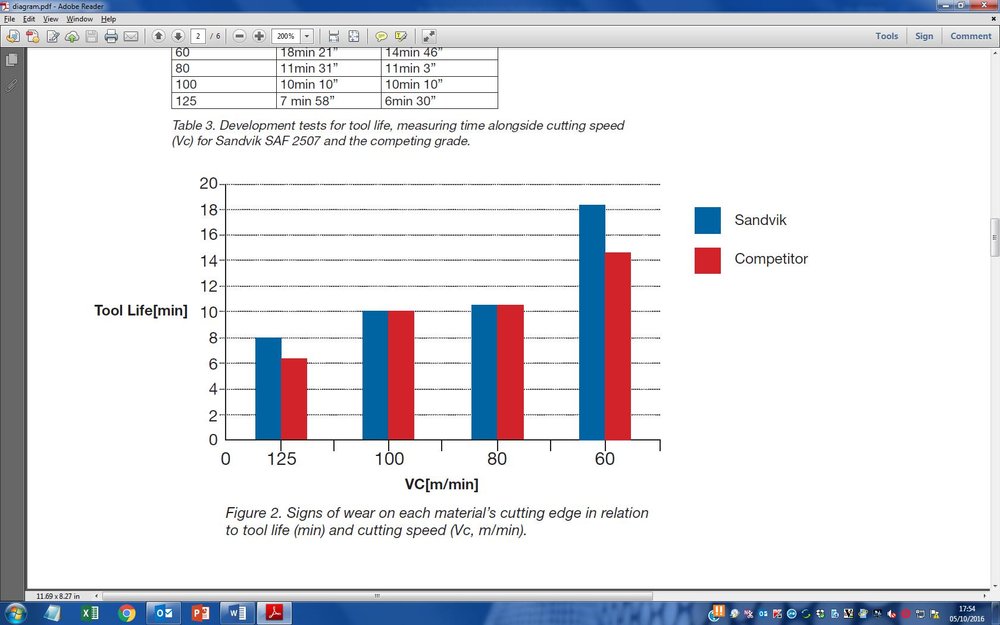

Visual examinations found greater signs of wear on European steel producer’s super-duplex after machining at the lowest (60 m/min) and highest (125 m/min) cutting speeds, and the Sandvik material’s tool life was significantly longer in these cases. The performance of each material was similar at the midrange speeds of 80 to 100 m/min. Figure 1 brings together the results.

Figure 1. Signs of wear on each material’s cutting edge in relation to tool life (min) and cutting speed (Vc, m/min).

Chip formation

Steel of optimal machinability should be soft enough to easily form a chip, yet brittle enough for that chip to break and separate.

For this reason, the second round of tests focused on chip formation to assess the effects of cutting depth and feed on each super-duplex material in component diameters of 100 mm and 40 mm. Both grades were machined at cutting speeds of 70 m/min and 90 m/min, using the same machining lathe as before.

A higher volume of chips was removed from Sandvik SAF 2507 than from the competing super-duplex at both machining speeds. This shows that the Sandvik grade offers superior machinability and favorable characteristics for longer tool life.

Drilling tests

The next testing stage involved drilling 257 holes in each material, into several discs cut at lengths of 60 mm from the same group of bars which had been assessed for turning. The holes were drilled to a depth of 26 mm, three-times the diameter, and parallel to the bar axis to ensure accurate cutting action.

The solid cemented carbide drill (manufactured by Sandvik Coromant) was afterwards inspected for visual signs of wear. Only 135 holes were drilled into the competitor’s super-duplex before the drill exceeded its wear limit, compared with 168 holes into Sandvik SAF 2507.

In addition, chips that had broken off each grade after 80 holes had been drilled were visually examined. Sandvik SAF 2507’s chips were ‘better’, which shows the grade required less power consumption in drilling.

Further analysis and hollow bar

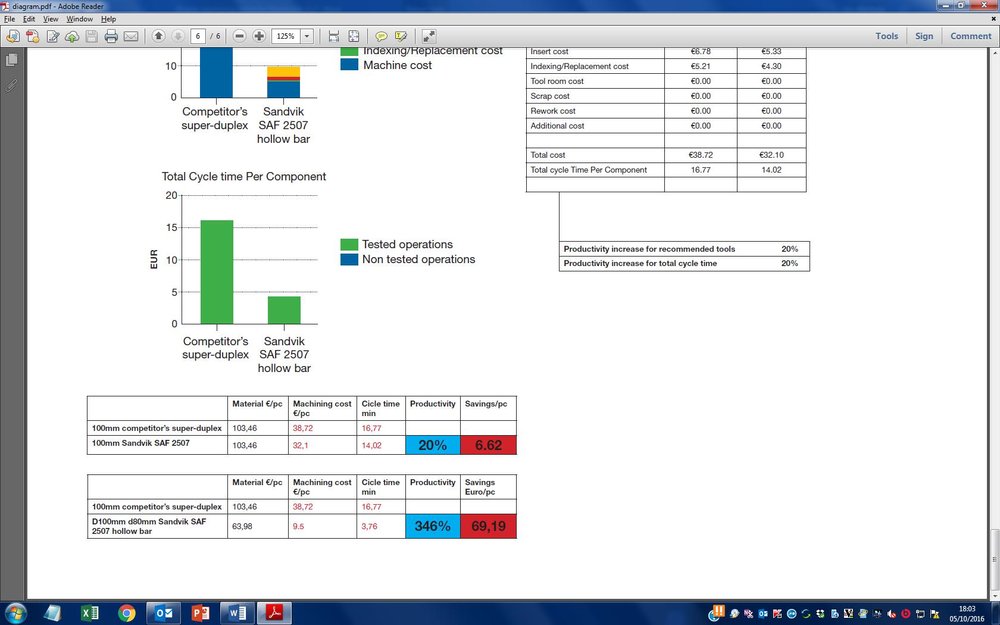

Of course, cost remains the key issue when choosing new materials for machining. Sandvik’s specialists turned to Productivity Analyzer software owned by Sandvik Coromant which accumulated various data - including tool cost, insert cost and the total cycle time – both for Sandvik SAF 2507 and the competing grade.

The findings determined that Sandvik SAF 2507 makes is possible to save 6,62 Euros per workpiece (€/pc) while increasing productivity by 20%. Table 1 shows the results.

Table 1. Accumulated data shows that Sandvik SAF 2507 is more cost-effective, even more so as hollow bar.

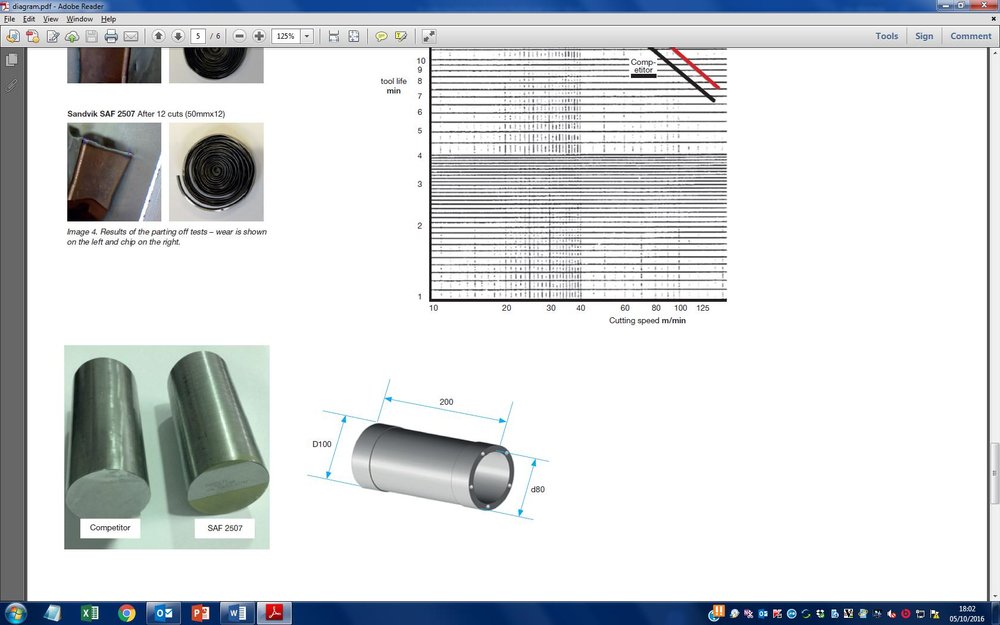

Table 1 also calculates the significant improvements in productivity and savings which are possible with Sandvik SAF 2507 in the form of hollow bar. Sandvik recommends hollow bar to further reduce machining time by eliminating the need for a central bore. Solid bar and hollow bar are both shown in Image 2.

Image 2. Sandvik SAF 2507 and the competing super-duplex shown in both solid bar (left) and hollow bar form.

Conclusions

While the extensive test findings at Sandvik Coromant’s facilities make it clear that Sandvik SAF 2507 can improve the productivity, competitiveness and profitability of workshops over the competitor’s super-duplex, operators’ investments can be lowered further still by opting for hollow bar instead of solid bar.