www.industryemea.com

15

'25

Written on Modified on

Hybrid Heating: Combining Silicone Heaters with Peltier / Thermoelectric Modules

Ohmvo offers a wide range of advanced heating elements and complete turnkey systems optimized for accurate temperature management.

ohmvo.com

While silicone rubber heating elements provide reliable performance, their cooling capability is limited. Conversely, thermoelectric modules can both heat and cool in a compact format but are restricted in overall heating capacity.

To overcome these challenges, hybrid configurations have gradually emerged as effective solutions for modern electronic and industrial applications.

From medical diagnostics and optical instruments to battery management systems, where rapid and precise response is essential, the combination of these two technologies enables superior performance by compensating for each other’s limitations.

Thinking about going hybrid in your own systems? This article will guide you through the key options to consider!

Integrating silicone and thermoelectric technologies enables optimized thermal management, achieving faster response times and stable temperature control across dynamic operating conditions.

At the Heart of Each Technology

Silicone Heaters

Silicone heating elements are composed of etched or wire-wound foil resistors embedded between layers of silicone rubber. Their highly flexible and adaptable structure provides uniform heat distribution and mechanical durability across a wide temperature range, typically reaching 200–230 °C.

Among the key characteristics:

. Power density: Up to 1.5 W/cm² depending on mounting and insulation

. Thermal uniformity: The etched-foil pattern minimizes hot spots and short circuits

. Integration: Can include embedded sensors (RTDs, thermistors, or thermocouples)

. Applications: Equipment warm-up, freeze protection, analytical instrumentation

However, these advantages come with certain limitations that should not be overlooked. Silicone heaters are inherently unidirectional, providing heat only. They convert electrical energy into thermal energy. When precise temperature control or cooling is required, alternative systems must be employed.

Thermoelectric (Peltier) Modules

The Peltier effect was discovered in 1834 by Jean Charles Athanase Peltier. He demonstrated that the utilization of current at the outskirts of two different materials results in the centralization of hotness and release of hotness at the subatomic level, which is frequently conducted with different vitality levels of materials, particularly N and P-type materials.

A Systematic Review of Thermoelectric Peltier Devices: Applications and Limitations.

A Peltier module operates on the Peltier effect, where an applied DC current drives heat transfer through semiconductor junctions, moving heat from one side to the other. This enables both heating and cooling, depending on the current direction.

When electrical energy is applied to the module, the positive and negative charge carriers absorb and release energy respectively. One side of the plate absorbs heat energy from one material surface and releases it to the other side. Reversing the supply terminals results in reversed hot and cold sides.

Thermoelectric (Peltier) Modules

© ohmvo

The heat pumped according to: [Q = alpha I T – frac{1}{2} I^2 R – k Delta T] where:

( alpha ) is the Seebeck coefficient (Seebeck being the first to discover, in 1821, that an electric current could flow in a circuit made from two completely different metals if the junctions were maintained at two different temperatures)

( I ) is the current

( R ) is the electrical resistance

( k ) is the thermal conductance between sides

While this type of installation offers quick reversibility, its low coefficient of performance (usually below 1 for heating) and its difficulty adapting to temperature fluctuations are nevertheless regrettable.

The Hybrid Concept

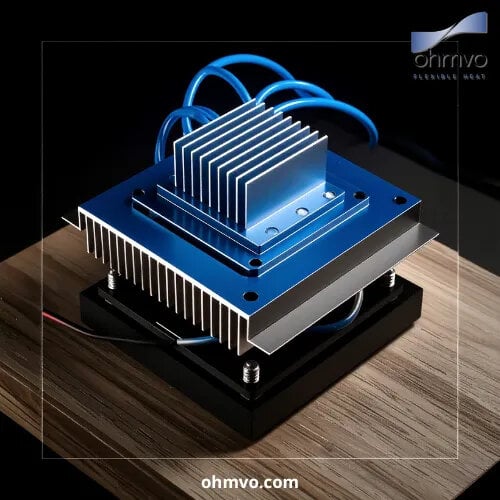

Forget about technical limitations by combining the strengths of each system! The hybrid heating system layers a silicone heating element with one or more thermoelectric modules.

At its core, a silicone heating element is bonded to a substrate or mounting plate. Then, a thermal interface material (TIM) serves as an intermediate layer, and finally, a heat sink is attached to the hot side of the Peltier module. In this setup, the silicone heating element handles heating and maintains a constant base temperature, while thermal regulation is managed by the Peltier module.

We can also note the presence of integrated temperature sensors, which help regulate the current of each device individually. While the silicone rubber heater manages major temperature variations, the Peltier module takes over when it comes to adjusting or reversing the heat flow as needed.

Why Choose the Hybrid Approach?

For its rapid thermal response and bidirectional control (features that make it particularly effective under variable ambient conditions), or because the system also ensures optimized temperature uniformity across the entire target surface.

In terms of energy efficiency, the fine-tuned adjustments provided by the Peltier module are a key advantage, while the dual-source configuration offers superior fault tolerance. In the event of a component failure, the other element continues to maintain safe thermal conditions.

Design Considerations and Best Practices

Use mica sheets or silicone encapsulants to ensure flawless electrical insulation, as both elements carry a significant current. For enhanced control, the heating channels and the Peltier module can be managed independently using a dual PID system implemented in a microcontroller (such as an FPGA) or even a programmable logic controller (PLC). Naturally, additional temperature sensors and thermal protection features can also be incorporated. In all cases, ensure compliance with safety standards such as UL 499 or IEC 60335, which apply to heating elements.

Finally, separate power rails are recommended for high-current loads. Include surge protection and current limiting to prevent overloads during transient conditions.

Applications

. Medical Devices: Compact analyzers, incubators, and diagnostic cartridges

. Battery Management Systems: Hybrid systems stabilize lithium-ion cells during charge/discharge cycles and extend lifespan

. Automobile Coolers: Gearboxes, cooling systems, and exhaust systems… In general, a vehicle’s heating, ventilation, and air conditioning (HVAC) system consists of mechanical refrigeration and absorption systems

. Optoelectronics: Laser diodes and photonic sensors require temperature stabilization within ±0.1 °C for wavelength stability

. Environmental Chambers and Sensors: Hybrid modules maintain controlled conditions in field-deployed instrumentation

. Electronic Devices: Employed to decrease heat dissipation

. Aerospace and Defense

Hybrid heating systems are therefore found in a wide range of industries and are expected to expand further as we learn to overcome the specific challenges they present.

We are now seeing the emergence of printed thermoelectric materials integrated directly onto heating substrates, which could help overcome thermal mismatches between materials. In another area, where complex control algorithms are required for coordinated operation, AI could gradually take over thermal management. Time will tell what the future holds for these technologies!

The Future of Hybrid Heating

The combination of silicone heating elements and Peltier modules delivers fast, stable, and reversible thermal systems. Perfect for bridging the gap between simple resistive heating and precise thermoelectric control.

Looking to discuss your industrial heating requirements? Ohmvo offers a wide range of advanced heating elements and complete turnkey systems optimized for accurate temperature management.

© ohmvo

The heat pumped according to: [Q = alpha I T – frac{1}{2} I^2 R – k Delta T] where:

( alpha ) is the Seebeck coefficient (Seebeck being the first to discover, in 1821, that an electric current could flow in a circuit made from two completely different metals if the junctions were maintained at two different temperatures)

( I ) is the current

( R ) is the electrical resistance

( k ) is the thermal conductance between sides

While this type of installation offers quick reversibility, its low coefficient of performance (usually below 1 for heating) and its difficulty adapting to temperature fluctuations are nevertheless regrettable.

The Hybrid Concept

Forget about technical limitations by combining the strengths of each system! The hybrid heating system layers a silicone heating element with one or more thermoelectric modules.

At its core, a silicone heating element is bonded to a substrate or mounting plate. Then, a thermal interface material (TIM) serves as an intermediate layer, and finally, a heat sink is attached to the hot side of the Peltier module. In this setup, the silicone heating element handles heating and maintains a constant base temperature, while thermal regulation is managed by the Peltier module.

We can also note the presence of integrated temperature sensors, which help regulate the current of each device individually. While the silicone rubber heater manages major temperature variations, the Peltier module takes over when it comes to adjusting or reversing the heat flow as needed.

Why Choose the Hybrid Approach?

For its rapid thermal response and bidirectional control (features that make it particularly effective under variable ambient conditions), or because the system also ensures optimized temperature uniformity across the entire target surface.

In terms of energy efficiency, the fine-tuned adjustments provided by the Peltier module are a key advantage, while the dual-source configuration offers superior fault tolerance. In the event of a component failure, the other element continues to maintain safe thermal conditions.

Design Considerations and Best Practices

Use mica sheets or silicone encapsulants to ensure flawless electrical insulation, as both elements carry a significant current. For enhanced control, the heating channels and the Peltier module can be managed independently using a dual PID system implemented in a microcontroller (such as an FPGA) or even a programmable logic controller (PLC). Naturally, additional temperature sensors and thermal protection features can also be incorporated. In all cases, ensure compliance with safety standards such as UL 499 or IEC 60335, which apply to heating elements.

Finally, separate power rails are recommended for high-current loads. Include surge protection and current limiting to prevent overloads during transient conditions.

Applications

. Medical Devices: Compact analyzers, incubators, and diagnostic cartridges

. Battery Management Systems: Hybrid systems stabilize lithium-ion cells during charge/discharge cycles and extend lifespan

. Automobile Coolers: Gearboxes, cooling systems, and exhaust systems… In general, a vehicle’s heating, ventilation, and air conditioning (HVAC) system consists of mechanical refrigeration and absorption systems

. Optoelectronics: Laser diodes and photonic sensors require temperature stabilization within ±0.1 °C for wavelength stability

. Environmental Chambers and Sensors: Hybrid modules maintain controlled conditions in field-deployed instrumentation

. Electronic Devices: Employed to decrease heat dissipation

. Aerospace and Defense

Hybrid heating systems are therefore found in a wide range of industries and are expected to expand further as we learn to overcome the specific challenges they present.

We are now seeing the emergence of printed thermoelectric materials integrated directly onto heating substrates, which could help overcome thermal mismatches between materials. In another area, where complex control algorithms are required for coordinated operation, AI could gradually take over thermal management. Time will tell what the future holds for these technologies!

The Future of Hybrid Heating

The combination of silicone heating elements and Peltier modules delivers fast, stable, and reversible thermal systems. Perfect for bridging the gap between simple resistive heating and precise thermoelectric control.

Looking to discuss your industrial heating requirements? Ohmvo offers a wide range of advanced heating elements and complete turnkey systems optimized for accurate temperature management.