www.industryemea.com

19

'26

Written on Modified on

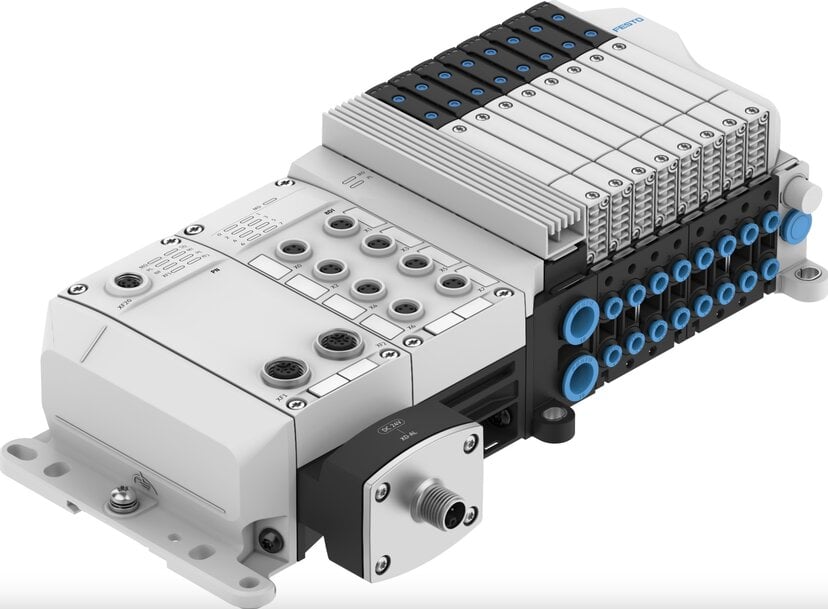

Festo Expands VTUX Valve Terminal with Advanced Connectivity and Energy Functions

Festo enhances the VTUX platform with Festo AP communication, smart vacuum integration and energy-saving valve functions to support modular, IIoT-ready machine designs.

www.festo.com

Festo has extended its VTUX pneumatic valve terminal platform with new communication options, smart vacuum capabilities and energy-optimised valve functions. The updates are designed to provide greater design flexibility, improved compressed air efficiency and enhanced digital integration for machine builders.

Modular Design and Optimised Pneumatics

The VTUX base system was introduced as a cost-optimised platform for pneumatic solenoid valve manifolds, offering high flow rates and modular configuration. Valve modules can be freely arranged, enabling compact and lightweight layouts that reduce installation time and machine footprint.

A key feature is the ability to split manifolds without requiring additional fieldbus nodes. This supports decentralised machine layouts, simplifies maintenance access and reduces overall system cost. Shorter pneumatic line lengths reduce dead volumes, improving actuator response times and cycle rates while lowering compressed air consumption.

The lightweight construction also allows installation on front-end units, portals or robot arms, supporting end-of-arm tooling applications with reduced moving mass and minimized piping complexity.

Digital Integration via Festo AP

The expanded VTUX platform integrates Festo AP (Automation Protocol), enabling open digital communication across electrical and pneumatic subsystems. Festo AP supports scalable centralised, decentralised or hybrid architectures and allows integration into Ethernet-based fieldbus networks.

The CPX-AP-I remote I/O system with IP65/67 protection enables real-time communication, while compatibility with IO-Link and direct fieldbus interfaces ensures flexible integration. The CTED multi-protocol node enables compact connectivity to common Industrial Ethernet hosts, reducing interface complexity.

Through Festo AP, VTUX becomes part of a digitised automation environment, supporting sensor integration, diagnostics and data exchange for Industrial Internet of Things (IIoT) applications. This architecture enables predictive maintenance and improved machine transparency.

Smart Vacuum and I/O Flexibility

New optional input modules enhance flexibility for commissioning and diagnostics. In addition, individual valve slices can be equipped with integrated smart vacuum generators, reducing external tubing and cabling.

For end-of-arm applications, integrated vacuum functionality shortens compressed air paths and decreases wear points. Reduced footprint and lower moving mass contribute to improved robot dynamics and faster handling cycles.

Energy Efficiency with Smart Switch Lite

The Smart Switch Lite function introduces a 5/4-way valve option that temporarily switches off supply air during cylinder motion. Residual expansion energy ensures the actuator reaches its end position while reducing compressed air consumption.

Cylinder chambers can be individually exhausted and blocked, allowing controlled pressure reduction in the end position. This approach supports dynamic subsequent movements and optimised cycle times while lowering overall energy use.

Scalable Platform for Future-Ready Machines

With integrated safety functions, open communication and modular pneumatic configuration, the enhanced VTUX platform supports scalable machine concepts from compact standalone units to complex networked systems.

By combining digital connectivity, reduced piping volumes and energy-saving valve control, the updated VTUX enables more responsive and resource-efficient automation architectures.

www.festo.com