www.industryemea.com

08

'18

Written on Modified on

New Vertical Milling Machine for 5-Sided Machining

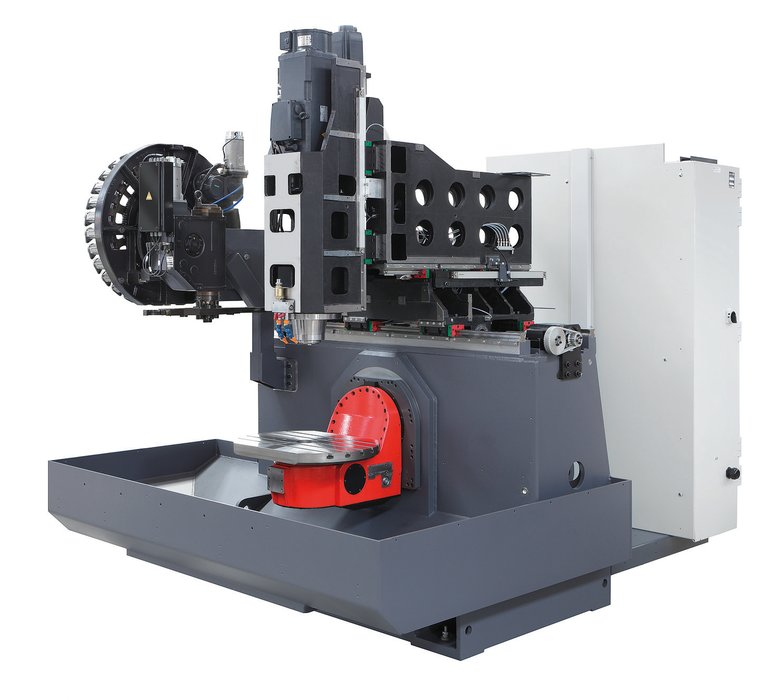

With the new MAXXMILL 630, EMCO customers can enjoy a flexible vertical CNC milling machine for 5-sided machining. Complex workpieces with an edge length of 445 x 445 x 290 mm can be efficiently and precisely machined in one setting. The compact machine structure and excellent value for money also support customers in making further advantageous savings.

HALLEIN – TAXACH. 5-sided machining in just one setting, compact machine design, maximum precision, 'Made in the Heart of Europe’, the latest control technology - and all of this at an outstanding price-performance ratio. The machine's selling points are impressive from a technical, qualitative and, not least, financial point of view.

The machine's enclosed cast iron and welded steel construction offers maximum stability and thermal symmetry. Short force flows ensure optimum precision and excellent surface qualities on the workpiece. The chip removal can be handled by an optionally available chip flushing system and a hinge-type chip conveyer.

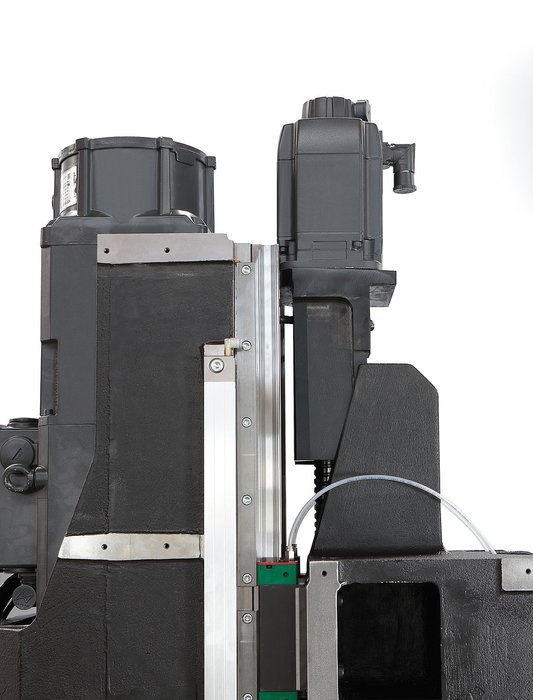

Depending on the production requirements, a powerful mechanical spindle with a maximum speed of 12,000 rpm or a water-cooled motor spindle with a maximum speed of 15,000 rpm can be selected.

As the tool magazine holds 30 tool stations ready for use, complex machining processes can be carried out simply and efficiently. The user can choose between ISO40 and BT40 tool holders. Besides, the motor spindle may also be acquired with a DIN69872 pull stud and HSK-A63.

The MAXXMILL 630 can be programmed using the latest control technology from either Siemens or Heidenhain. The control unit is attached to an ergonomic control panel that is inclined to the front and equipped with a rotary function. This guarantees easy work processes.

Naturally, EMCO's commitment "Made in the Heart of Europe" also applies to the MAXXMILL 630. The machines are completely developed and produced in Europe in cooperation with European brand manufacturers that meet the highest standards in terms of quality, productivity and efficiency.

The MAXXMILL 630 is therefore the ideal vertical milling centre for the 5-sided machining of parts in low or medium quantities. This makes it particularly suitable for contract manufacturers, industrial enterprises such as automotive supply companies, general mechanical manufacturing and higher-level training institutions.

Technical Data:

Travels and tolerances

X-axis travel [mm] 500

Y-axis travel [mm] 460

Z-axis travel [mm] 450

Tilting range B-axis +/- 100°

Rotating range C-axis n x 360°

Rapid traverse X/Y/Z [m/min] 30

Table

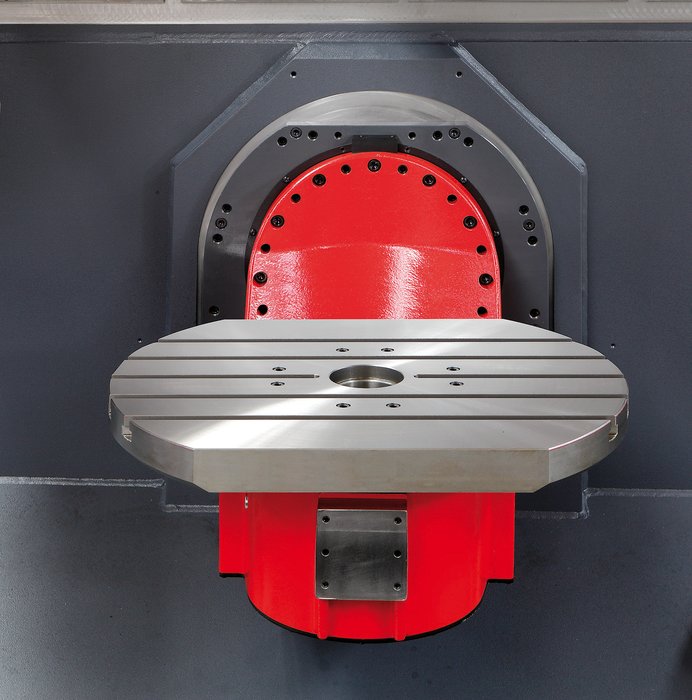

Length x width [mm] 630 x 500

Max. work piece weight [kg] 200

Main spindle (mechanical spindle)

Speed range [rpm] 50 – 12 000 (not continuous)

Spindle power [kW] 15

Torque [Nm] 100

Main spindle (motor spindle)

Speed range [rpm] 50 - 15000

Spindle power [kW] 20

Torque [Nm] 100

Tool magazine

Number of tool stations 30

Tool change time (tool - tool) [sec] 2

Max. tool diameter [mm] 80

Max. tool length [mm] 250

Max. tool weight [kg] 8

630 x 500 mm table; workpiece weight of up to 200 kg

About EMCO

Salzburg-based EMCO is one of Europe's leading machine tool manufacturers. Its two commitments "Made in the Heart of Europe" and "Design to Cost" are the main factors in the success of the international company, which represents excellent production quality and functional design. EMCO is part of the KUHN Holding and currently employs around 690 staff at a total of 6 production facilities in Austria, Germany, Italy and Russia.

Further information can be found online at www.emco-world.com

Contact:

EMCO GmbH.

Christa Vergnes, e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Salzburger Strasse 80, Postfach, 5400 Hallein-Taxach AUSTRIA

Tel.: +43-6245-891-0, Fax: +43-6245-86965

Internet: www.emco-world.com