www.industryemea.com

31

'22

Written on Modified on

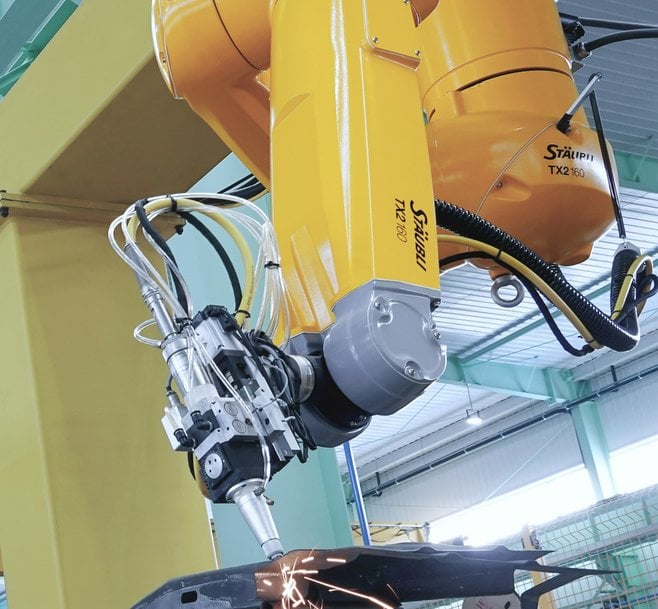

Stäubli unveils new TX2-160L HDP laser cutting robot at Automatica 2022

Stäubli recently launched the TX2-140 and the larger TX2-160, two new six-axis machines for the medium payload range. At booth 329 in hall B5 at this year's Automatica, the TX2-160L HDP, a special version for fiber laser cutting, is now celebrating its premiere.

“This robot sets the benchmark in terms of laser cutting,” says Christophe Coulongeat, Executive President at Stäubli Robotics. “It is superfast and ultraprecise, as well as having a long reach and an exceptionally rigid structure – a combination of properties that makes it the number one choice in fiber laser cutting.”

A quick look at the data sheet of the HDP (High Dynamic Precision) robot confirms the Executive President’s assertion. The legendary JCS drive technology, a proprietary invention of Stäubli Robotics, is what guarantees the high dynamics and accuracy. In the TX2-160L HDP, Stäubli engineers have taken precision to the next level with the incorporation of an ingenious absolute measurement feature. The fine-tuned six-axis robot achieves a repeatability that surpasses even that of the standard TX2-160L model which, with its accuracy of ± 50 µm, is already one of the most precise robots on the world market.

Stäubli’s success in extending JCS drive technology from the basic axes to axis 5 brings further decisive advantages: the robot now has significantly enhanced stiffness of wrist and achieves impressive dynamics. The maximum speed on the fifth axis is 1,500 rps.

The TX2-160L six-axis robot has been optimized for fast and precise cutting to produce the new TX2-160L HDP version.

Highly flexible and exceptionally versatile

With a reach of just over two meters, the TX2-160L HDP can cut geometric shapes as well as complex free-form surfaces in three dimensions with unprecedented accuracy. It has been designed for use with fiber lasers supplied by any of the current manufacturers.

The Stäubli engineers are also particularly proud of the highly compact design of this robot. The manufacturer is thus fulfilling the wish of many integrators and end users for an easy-to-integrate six-axis machine with a small footprint that facilitates the realization of production cells and lines in minimum factory space. The machine is equally suitable for floor and ceiling mounting.

With its extensive safety features, Industry 4.0 compatibility (including OPC-UA server), mechanical qualities and above-average maintenance intervals, the new TX2-160L HDP looks set to quickly establish itself in classic and digitally networked environments.

www.staubli.com