The quick and easy way to achieve a linear dispensing robot

New Smart Function Kit for Dispensing enables a wide range of dispensing tasks to be carried out more quickly and is compatible with all commercially available dispensing heads.

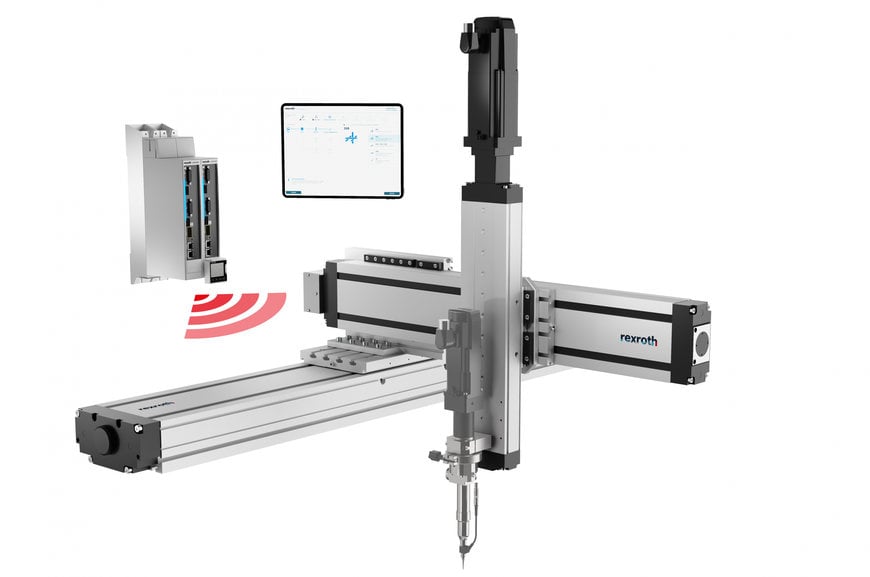

New Smart MechatroniX platform solution package: The universal Smart Function Kit for Dispensing, here with a fully integrated dispensing head from the manufacturer ViscoTec.

- Time saving: Easy product selection, guided commissioning

- Plug and produce: Pre-assembled subsystems, intuitive operating software

- Swift start to production: Graphic sequencing, straightforward line integration

- Partnership: ViscoTec dispensing heads already integrated into the software

Bosch Rexroth is continuing to drive the digital transformation of linear motion technology and is adding another subsystem to the Smart MechatroniX solution platform: The Smart Function Kit for Dispensing enables users to carry out typical dispensing tasks such as bonding and sealing more quickly and easily than ever before. The subsystem combines best-in-class linear motion technology with automation hardware and intuitive software to form complete linear robots, which can be quickly digitally selected and configured and, thanks to pre- installed operating software, can start production within just a few minutes. The Smart Function Kit is universal and supports all common dispensing heads.

Manufacturers, system integrators and mechanical engineers across numerous industries, such as the automotive, packaging, battery manufacturing and semi-conductor manufacturing industries, need to carry out typical dispensing tasks such as bonding, sealing, spraying, filling and casting more quickly, easily and cost-effectively. Bosch Rexroth is now able to fulfil this customer requirement with the Smart Function Kit for Dispensing.

Like the Smart Function Kit for Handling and the Smart Function Kit for Pressing, is this new subsystem also part of the Smart MechatroniX solution platform, which combines linear motion technology, software and sensors to smart products and fast usable solution packages. In order to achieve upward integration in the area of linear robotics, Bosch Rexroth offers new solutions for an extremely wide range of motion tasks in quick succession.

The Smart MechatroniX platform is not only being expanded horizontally with new solution packages but is also growing vertically thanks to partnerships. As a result of the latest collaboration, ViscoTec’s dispensing heads can be used with the Smart Function Kit for Dispensing very quickly and easily. To ensure this, specific parameters are already recorded in the subsystem so that they can be read by the software and taken into consideration during set- up. Other manufacturers are expected to be integrated in the future.

The open ctrlX AUTOMATION platform provides a standardized control environment for the Smart Function Kits. The operating software runs as an app on the ctrlX CORE control system for the Smart Function Kit. The flexible combination of hardware platform and innovative software in this case enables, for example, complex line movements to be mapped using simple graphic programming. The line integration is also carried out easily via a function block.

The Smart Function Kit for Dispensing combines coordinated components to form a complete and virtually ready-to-use linear robot – including control technology, energy supply system, motors, connection elements and operating software. an individual solution package can be sized and selected very fast with LinSelect sizing . Pre-defined structural construction types make the product selection process much easier. Following corresponding parameterization, the subsystem is fully configured online and can then be ordered. The compatible dispending head is supplied by the relevant partner.

The pre-installed software reduces the amount of time usually taken for commissioning by up to 80%. A wizard guides the user through the process. The parameterization of the servo drive and – in the case of fully integrated partner attachments – of the dispensing head as well as the axis referencing are carried out automatically.

Instead of laboriously defining the process flow with lines of code, the movements can be graphically sequenced using ready-made function blocks, including dispensing functions, such as dosing, rinsing or needle-wiping.

Diagnostics tools for fast troubleshooting are also included in the software scope. A web-based dashboard provides an overview of efficiency, program flow and production history and, as such, supplies current process data such as position, flow rate and cycle time.

www.boschrexroth.com