www.industryemea.com

02

'23

Written on Modified on

KSB GROUP LAUNCHES NEW GENERATION OF PNEUMATIC 90° QUARTER-TURN ACTUATORS

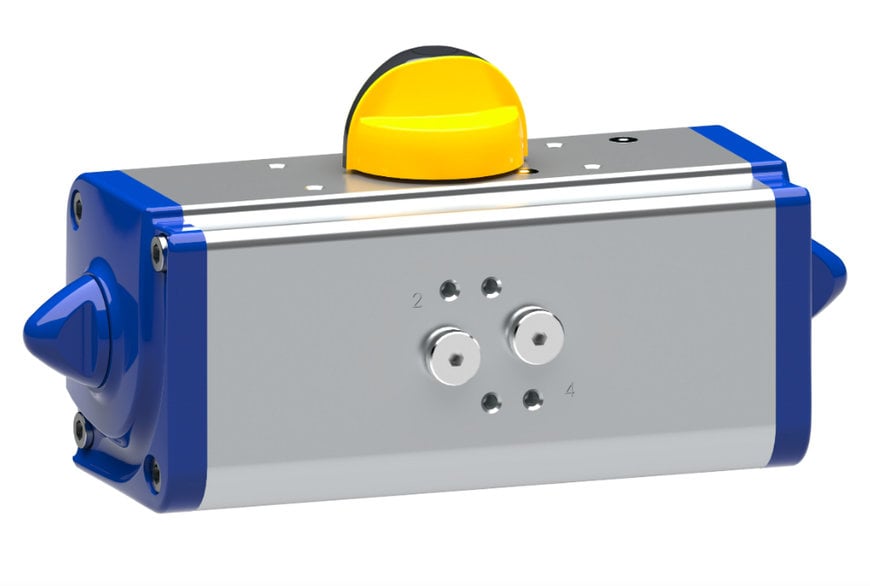

The double-acting and single-acting pneumatic actuators of the ACTAIR EVO and DYNACTAIR EVO type series are designed for actuating all types of part-turn valves, such as butterfly valves, ball valves and plug valves.

Double-acting and single-acting pneumatic actuators of the ACTAIR EVO and DYNACTAIR EVO type series from the KSB Group (©KSB SE & Co. KGaA)

Applications covered by the actuators are water treatment, wastewater treatment, power generation, general industry, refinery engineering and shipbuilding.

The double-piston actuators can be operated with compressed air to ISO 8573-1 from 3 to 8 bar. The maximum torque is 8000 Nm for the double-acting type series and 4000 Nm for the single-acting variant. The maximum ambient temperatures should be between -50 °C and +150 °C. With their IP68 enclosure, the actuators are suitable for use in a maritime environment. This means that – in the event of flooding – they will remain water-tight for about 169 hours at a depth of up to 30 metres.

The pneumatic connections comply with the NAMUR requirements. For mounting the necessary control units, every actuator is designed with interfaces to the VDI/VDE 3845 standards. Connection to the valve is via an ISO mounting interface to ISO 5211. The scotch yoke mechanism of these pneumatic actuators provides a variable torque, with the peak torque being effective for closing the valve.

As standard, the actuator is fitted with a position indicator and adjustable mechanical stops. The actuators are lubricated with silicone-free grease at the factory, their gear housings are made of anodised aluminium alloy. With their standardised interfaces, the actuators can be connected to higher-level process control systems with solenoid valves, positioners and diverse digital and analogue control units.

Applications covered by the actuators are water treatment, wastewater treatment, power generation, general industry, refinery engineering and shipbuilding.

The double-piston actuators can be operated with compressed air to ISO 8573-1 from 3 to 8 bar. The maximum torque is 8000 Nm for the double-acting type series and 4000 Nm for the single-acting variant. The maximum ambient temperatures should be between -50 °C and +150 °C. With their IP68 enclosure, the actuators are suitable for use in a maritime environment. This means that – in the event of flooding – they will remain water-tight for about 169 hours at a depth of up to 30 metres.

The pneumatic connections comply with the NAMUR requirements. For mounting the necessary control units, every actuator is designed with interfaces to the VDI/VDE 3845 standards. Connection to the valve is via an ISO mounting interface to ISO 5211. The scotch yoke mechanism of these pneumatic actuators provides a variable torque, with the peak torque being effective for closing the valve.

As standard, the actuator is fitted with a position indicator and adjustable mechanical stops. The actuators are lubricated with silicone-free grease at the factory, their gear housings are made of anodised aluminium alloy. With their standardised interfaces, the actuators can be connected to higher-level process control systems with solenoid valves, positioners and diverse digital and analogue control units.

www.ksb.com