www.industryemea.com

06

'23

Written on Modified on

ABB AND ALTILIUM SIGN AGREEMENT TO WORK ON BATTERY INDUSTRY RECYCLING PROJECTS

ABB and Altilium signed a Memorandum of Understanding to explore automation, electrification and digital solutions for European battery recycling plants.

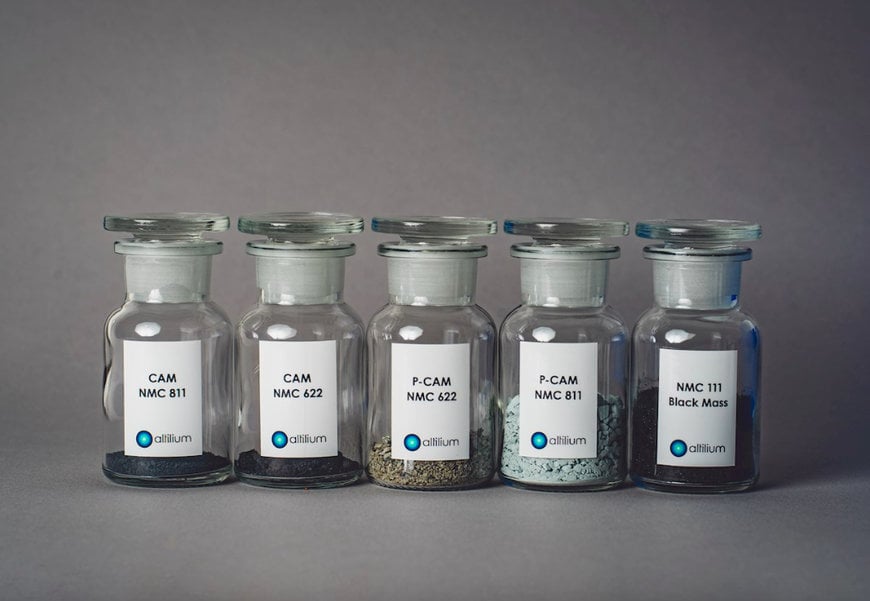

ABB and Altilium will explore how automation, electrification and digital technologies in plants across Europe can support the scaling up of battery materials recycling. Image: Altilium

ABB has signed a Memorandum of Understanding (MoU) agreement with UK-based clean technology group Altilium to jointly explore how the integration of automation, electrification and digital technologies in plants across Europe can support the scaling up of battery materials recycling. Altilium is developing green processing technologies and building infrastructure at scale for the recycling of metals and electric vehicle (EV) battery waste, with the aim of ensuring a domestic supply chain of low-carbon battery materials for the automotive industry.

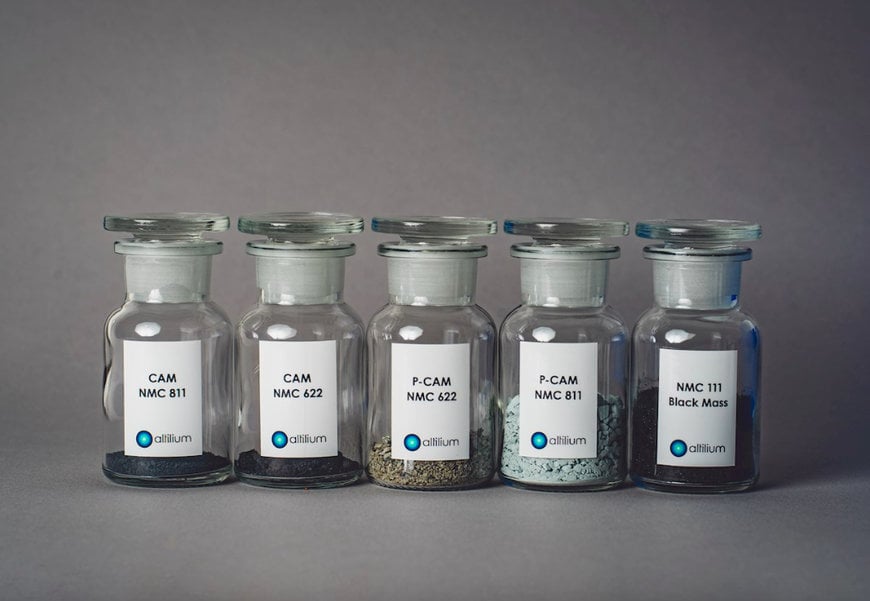

ABB will introduce the design and delivery of control systems equipment and solutions for the distribution and management of electrical power for Altilium’s UK pilot battery recycling scheme, which will produce battery-ready cathode active material (CAM) from used EV batteries. The global technology leader will also explore the use of its ABB Manufacturing Operations Management (MOM) and Manufacturing Execution System (MES) digital applications. Such integrated automation standardizes and optimizes processes with intuitive interfaces and edge data collection.

The two companies plan to extend their work into commercial plants. This includes the retrofit of Altilium’s European Solvent Extraction-Electrowinning (SX-EW) facility in Eastern Europe, which will start processing battery waste in 2024; and the development of a planned UK plant in Teesside from 2026 that will create 20 per cent of the country’s required CAM, making it one of the largest projects in the region.

Altilium’s pilot battery recycling scheme will produce battery-ready cathode active material (CAM) from used EV batteries. Image: Altilium

World Economic Forum figures show the demand for batteries is expected to increase 14-fold by 2030 due to the adoption of electric vehicles. As an increasing number of these batteries reach end-of-life, it is critical they are recycled to ensure a reliable, sustainable supply of critical minerals.

ABB’s technology and approach will allow Altilium to speed up its time to market, supporting the provision of scalable solutions as the company expands its operations, and will significantly reduce the carbon footprint of EV batteries, aligning with both companies' commitment to a greener future. It is the latest example of ABB’s technology being put to good use in the recycling of used batteries.

Altilium opened its EV Battery Recycling Technology Centre in Devon in 2022 and is currently the only company in the UK producing CAM recovered from EV battery waste. Its first European plant will recycle battery waste from over 24,000 vehicles a year, while the UK facility, to be located in Teesside, will process waste from over 150,000 EVs per year, producing 30,000 metric tons of CAM.

ABB has signed a Memorandum of Understanding (MoU) agreement with UK-based clean technology group Altilium to jointly explore how the integration of automation, electrification and digital technologies in plants across Europe can support the scaling up of battery materials recycling. Altilium is developing green processing technologies and building infrastructure at scale for the recycling of metals and electric vehicle (EV) battery waste, with the aim of ensuring a domestic supply chain of low-carbon battery materials for the automotive industry.

ABB will introduce the design and delivery of control systems equipment and solutions for the distribution and management of electrical power for Altilium’s UK pilot battery recycling scheme, which will produce battery-ready cathode active material (CAM) from used EV batteries. The global technology leader will also explore the use of its ABB Manufacturing Operations Management (MOM) and Manufacturing Execution System (MES) digital applications. Such integrated automation standardizes and optimizes processes with intuitive interfaces and edge data collection.

The two companies plan to extend their work into commercial plants. This includes the retrofit of Altilium’s European Solvent Extraction-Electrowinning (SX-EW) facility in Eastern Europe, which will start processing battery waste in 2024; and the development of a planned UK plant in Teesside from 2026 that will create 20 per cent of the country’s required CAM, making it one of the largest projects in the region.

Altilium’s pilot battery recycling scheme will produce battery-ready cathode active material (CAM) from used EV batteries. Image: Altilium

World Economic Forum figures show the demand for batteries is expected to increase 14-fold by 2030 due to the adoption of electric vehicles. As an increasing number of these batteries reach end-of-life, it is critical they are recycled to ensure a reliable, sustainable supply of critical minerals.

ABB’s technology and approach will allow Altilium to speed up its time to market, supporting the provision of scalable solutions as the company expands its operations, and will significantly reduce the carbon footprint of EV batteries, aligning with both companies' commitment to a greener future. It is the latest example of ABB’s technology being put to good use in the recycling of used batteries.

Altilium opened its EV Battery Recycling Technology Centre in Devon in 2022 and is currently the only company in the UK producing CAM recovered from EV battery waste. Its first European plant will recycle battery waste from over 24,000 vehicles a year, while the UK facility, to be located in Teesside, will process waste from over 150,000 EVs per year, producing 30,000 metric tons of CAM.

www.abb.com