www.industryemea.com

28

'23

Written on Modified on

SIGMATEK at the SPS Nuremberg: New Safety Functions in the Drive and Digital Twin

Under the slogan “We Max Up Your Automation” SIGMATEK is continuously expanding and optimizing its portfolio. The user should have flexibility and convenience in the implementation of his application.

Two highlights at the SPS in Nuremberg are the extensive, TÜV certified safety functions of the MDD 2000 servo drives, which combine high performance with the greatest possible safety, and model-based development with the Digital Twin. This helps machine manufacturers to build better machines in less time.

Servo Drives MDD 2000: Even more Safety Functions Integrated in the Standard

The SIGMATEK DIAS-Drive 2000 series combines high power density and flexibility for servo motor control in a highly compact design. Now even more safety functions are integrated in the MDD 2000 servo drives. In addition to the most important Safe Torque Off (STO), Safe Stop 1 (SS1), Safe Operating Stop (SOS), Safe Brake Control (SBC) and Safely-Limited Speed (SLS) functions already included, 12 further safety functions are now available: safe speed, acceleration, position and rotating direction functions – all SIL 3, PL e, Cat. 4 and TÜV certified.

For precisely fitting drive solutions, the flexible servo system can be operated single-phase or three-phase with 230-480 VAC. In addition to one to three axes, supply, line filter, braking resistor and DC link are also on board - and all this on only 75x240x219 mm in size 1. Thus, the highest power density is achieved.

Size 1 offers a capacity of up to 3x 5 A nominal or 3x 15 A peak current, the double-width size 2 up to 3x 10 A nominal or 3x 30 A peak current. The overload factor is up to 300 percent. Very short controller cycle times of 62.5 µs give the DIAS drives excellent servo performance. The modules can be used standalone or in combination with any number of MDD-2000 axis modules of both sizes. They can be connected without tools using baying technology. This eliminates the need for complex individual wiring for power, DC link.

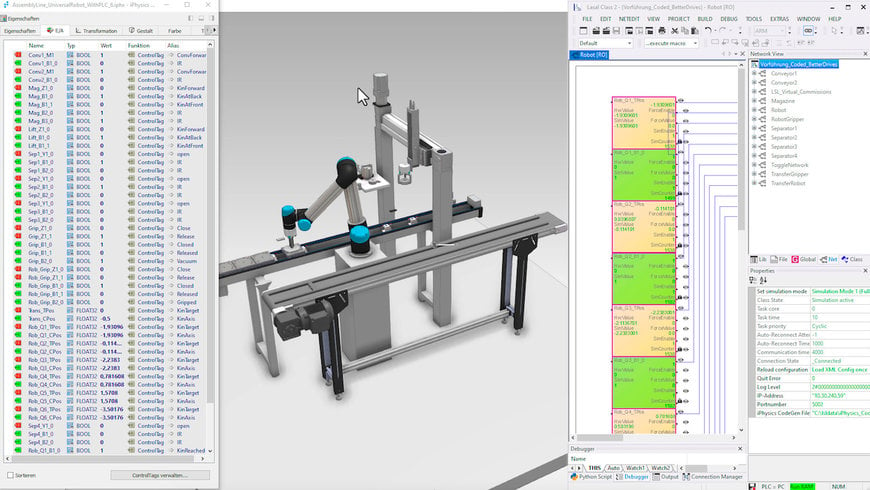

The Digital Twin of a machine or system helps to eliminate reworking and shorten the overall engineering time.

Digital Twin in LASAL: Faster to Better Machines through Parallelization

The LASAL software development environment from SIGMATEK supports model-based development and virtual commissioning with the Digital Twin.

In this process, together with 3D models of the mechanics, a complete Digital Twin is created for the physics-based 3D simulation. It acts as a valid basis for the detailed software development, electrical planning and design of a machine or plant. This makes it possible to virtually represent, simulate, test and validate all development steps from planning to commissioning - whether individual machine functions or complete systems.

For machine builders model-based system development with the Digital Twin brings many benefits – such as minimizing risks during software creation and a shorter time-to-market.

One advantage of this model-based development with the Digital Twin is to parallelize and thus accelerate the development. In addition, there is no need to wait for the real mechanics and hardware to be available before tuning and testing. As another essential step towards better machines, there is the possibility of virtual commissioning. The Digital Twin replaces the real machine or system. This is initially simulated completely as a computer model with "software in the loop". Only then the transfer of the programs to the real control hardware follows ("Hardware in the Loop").

To make this possible, all outward I/O object classes have been significantly extended in the LASAL development tool. These "advanced I/Os" no longer necessarily need real connections at their "outer" end, but can work in various modes with predefined, simulated or values created in the Digital Twin. This helps shorten development time, minimize development risk, and eliminate rework. Machine and system manufacturers can thus develop better machines faster and secure their market position.

To support model-based design and virtual commissioning, all outward-facing I/O object classes were expanded in the LASAL software design environment from SIGMATEK.

The application possibilities of the Digital Twin, however, are far from exhausted with commissioning. This can run during operation to detect deviations and take the appropriate actions. The error tolerance as well as the lifespan of the machine is therefore increased and predictive maintenance is enabled.

SIGMATEK at the SPS: Hall 7, Stand 270.

www.sigmatek-automation.com