www.industryemea.com

04

'23

Written on Modified on

Velo3D Names Schoeller-Bleckmann Oilfield Technology Its Sole Contract Manufacturing Partner in the DACH Region

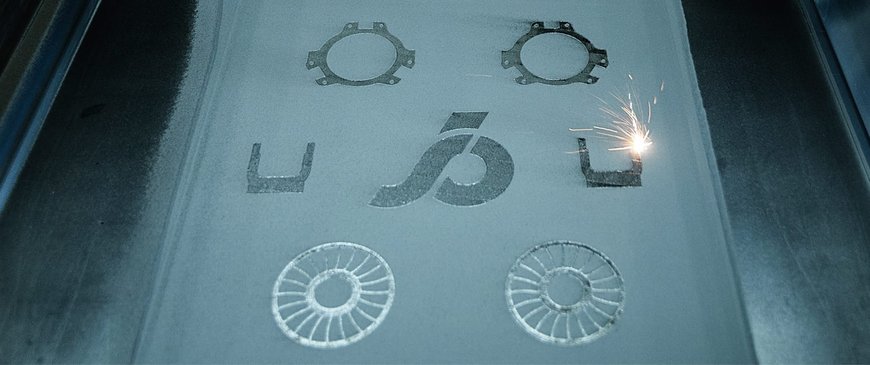

The Austria-based Manufacturer Currently Operates Two Velo3D Sapphire Printers, Including a Large-format Sapphire XC Printer, and Will Add an Additional Sapphire Printer to Its Facility.

Velo3D, Inc., a leading metal additive manufacturing technology company for mission-critical parts, today named Schoeller-Bleckmann Oilfield Technology (SBOT), a manufacturer of high-tech metal components with more than 100 years in business, its sole contract manufacturing partner operating in the DACH region, which includes Germany, Austria, and Switzerland. The company will also be established as Velo3D’s sole contract manufacturing partner for Europe’s oil and gas industry, which is SBOT’s primary industry it serves.

Through the agreement, SBOT will also add another Sapphire printer to its two existing printers that are currently in operation at its facility, including a Sapphire XC. As Sapphire production capacity maximum is reached, SBOT will add new printers and alloys to its network to support customers’ needs.

“Since purchasing our first Sapphire printer in 2021, we’ve been very impressed by Velo3D’s metal 3D printing solution and its ability to produce parts with few-to-no supports, even those with low and zero-degree overhangs,” said Campbell MacPherson, SBO EVP of Advanced Manufacturing. “It’s great to see Velo3D’s commit to our success with this agreement, which we believe will drive increased revenue for our additive manufacturing business. We look forward reaching new customers with our solutions from Velo3D and in turn reinvesting in our joint business together.”

Velo3D’s Contract Manufacturer Network allows companies to purchase metal 3D printing services from providers, rather than purchase, set up, and operate their own printer and its accompanying software. It also gives companies access to a wider variety of metal alloys. In doing so, companies can more easily take advantage of Velo3D’s fully integrated solution without a large capital expenditure. As production ramps up for these customers, they can then purchase their own printers or scale production to other providers to achieve a distributed manufacturing network.

There are currently more than 10 companies in Velo3D’s Contract Manufacturer Network across four continents. SBOT will now be the sole company in the network focused on the DACH region and Velo3D will not pursue new contract manufacturers within the European oil and gas industry, which comprises a large number of SBOT’s customers.

In 2021, Velo3D expanded its presence in Europe, with SBOT becoming the company’s first European member of its Contract Manufacturer Network. SBOT’s sister company, Knust-Godwin, had operated a fleet of Sapphire printers at its Katy, Texas, facility, which inspired SBOT to explore using Velo3D’s fully integrated solution for its customers serviced from its Austria facility.

“There is a growing demand for advanced manufacturing technology in Europe that can help companies streamline their supply chains, develop more performant parts, and lower manufacturing costs and SBOT is a great partner for European companies in need of high-quality metal parts,” said Benny Buller, Velo3D Founder and CEO. “Both SBOT and Knust-Godwin have been excellent partners that have continually demonstrated their ability to produce precise parts using the most advanced manufacturing technology available, and we’re honored to partner with them on this next phase of our growth in Europe.”

SBOT’s Sapphire printers are calibrated to produce parts using Inconel 718 powder, which is a nickel-based alloy that provides high strength and corrosion resistance at extreme temperatures. Its new Sapphire printer will produce parts in CP1, which is a lightweight aluminum alloy that is ideal for heat transfer applications. In addition to its Sapphire printers, SBOT operates 120 CNC machines with unique manufacturing technologies. The company is ISO 9001, ISO 14001, EN/AS 9100, API Spec 7-1, and AEO certified.

www.velo3d.com