www.industryemea.com

25

'24

Written on Modified on

Three additional BETA wire rope winches from Columbus McKinnon to accommodate larger ships on the slipway in Meppen

Columbus McKinnon Engineered Products has supplied three new BETA wire rope winches to the Ems-Nordsee Waterways and Shipping Authority for the Meppen building yard slipway since 2012.

The built-in three-phase motor with a power output of 4 kW can move tensile loads of up to 12 tonnes at travel speeds of up to 2 m/min. The motor runs smoothly due to the low-maintenance spur gear. The trolleys can be lowered into the water without power (emergency operation) using a drum release and a band brake. The pre-tension of each winch can be adjusted individually using a hand wheel. The existing winch system has been upgraded to enable the safe and reliable movement of longer vessels of up to 36 m and a total weight of approximately 300 tonnes on the slipway ramp.

The Pfaff-silberblau electric wire rope winches have been approved in accordance with the DGUV V54 (BGV D8) accident prevention regulations. All eight winches, which have synchronisation monitoring, meet the requirements for a safe machine as outlined in the German Ordinance on Industrial Health and Safety.

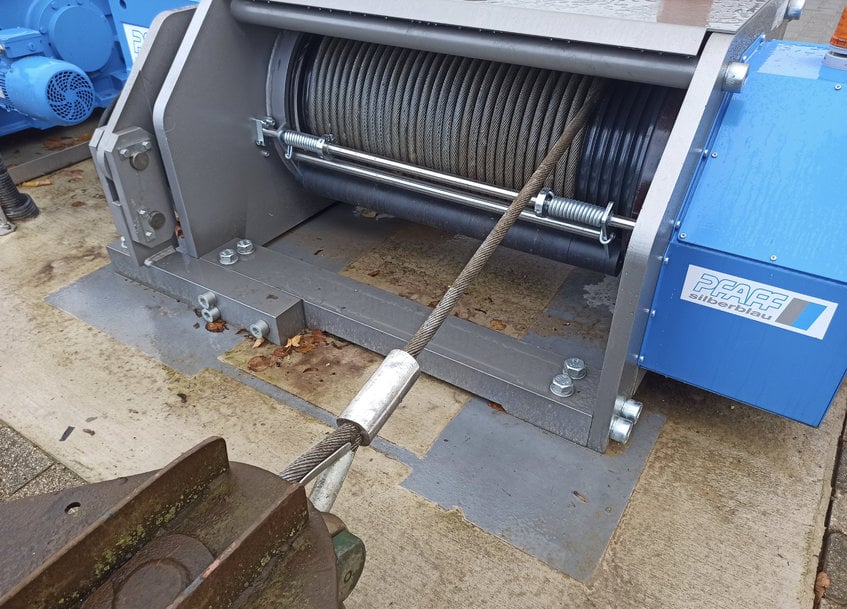

BETA wire rope winch as supplied

Ensuring the safe operation of the slipway, even with larger ships

The WSA Ems-Nordsee is responsible for ensuring smooth and safe navigation by operating, monitoring, and maintaining federal waterways and associated facilities. These facilities are maintained or renewed as required. A slipway, such as the one in the Meppen building yard, is an inclined ramp on which a vessel is pulled out of the water by means of rail-guided trolleys and lowered back into the water, for example for inspection and maintenance purposes. The wire rope winches required for this are operated from a central control station.

BETA wire rope winch in outdoor use

Until now, the slipway at the Meppen building yard was designed for ships up to 30 metres in length. However, longer vessels are now being used by WSA Ems-Nordsee and the neighbouring office WSA Westdeutsche Kanäle. To accommodate this change, the existing system was upgraded with three additional BETA electric winches of identical design. The system was then re-commissioned as a complete system with a Declaration of Conformity from Columbus McKinnon Engineered Products, ensuring compliance with all relevant regulations.

Control system ensures synchronised operation of the winch group

The synchronisation control system developed by Columbus McKinnon ensures the synchronised operation of the eight winches in a row. This system allows for the differentiated selection of individual winches depending on the ship model and length. The control system, which includes a frequency converter, group pre-selection, and synchronisation monitoring, was updated for the eight winches.

8 BETA wire rope winches are now in operation

Additionally, some components were replaced to ensure it is up to date. The control system manages all pre-selected winches in complete synchronisation throughout the entire travel path, regardless of the load. An alarm is triggered when a winch approaches its maximum pull of 12 tonnes to prevent overloading. The entire system will automatically shut down if this limit is exceeded.

All slipway winches have an IP55 rating and are suitable for outdoor use. They have geared limit switches with two contacts, an absolute encoder and motor monitoring with PTC thermistors. The grooved rope drum can accommodate rope lengths of up to 47 metres. A rope pressure roller ensures perfect spooling.

Ships with a length of over 30 m and a weight of up to approx. 300 tonnes can be hauled in on the eight slipway trolleys

BETA wire rope winches from Columbus McKinnon Engineered Products are suitable for both safety-critical industrial applications and non-industrial applications such as public buildings, sports facilities, and stage technology. This versatility is highlighted in the following examples: BETA-EL electric wire rope winches.

www.cmco.com