www.industryemea.com

19

'24

Written on Modified on

ANDRITZ TO UPGRADE FLUE GAS TREATMENT SYSTEMS AT SÖDRA PULP MILL

The mechanical and electrical refurbishments will extend the ESPs’ lifetime and enable an increase of the boiler’s capacity.

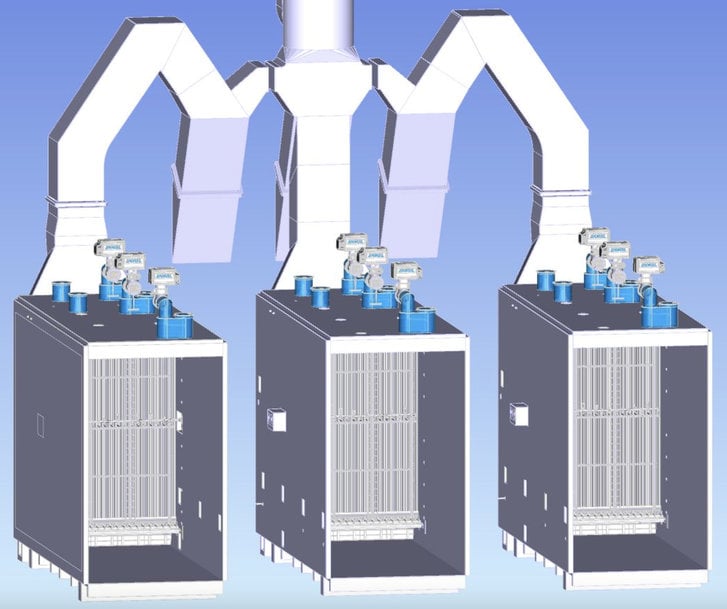

3D model of ANDRITZ SIR installation © ANDRITZ

Swedish forest industry group Södra has entrusted international technology group ANDRITZ with the upgrade of three electrostatic precipitators (ESPs) for the recovery boiler at the Mörrum pulp mill.

ANDRITZ will replace the discharge electrodes and collecting plates in the ESPs’ first fields and install state-of-the-art high voltage energization units – Switched Integrated Rectifiers (SIR) – in all fields. These latest-generation SIRs, equipped with silicon carbide power electronics, offer the highest electrical efficiency in the market, resulting in considerable energy savings for plant operators. ANDRITZ’s multipeak electrodes will enhance the recovery of residual salts to be recirculated into the process.

This upgrade will be carried out on one ESP at a time and does not require costly and time-consuming field extensions. As a result, downtime of the recovery boiler and impact on the mill’s production will be reduced to a minimum.

Swedish forest industry group Södra has entrusted international technology group ANDRITZ with the upgrade of three electrostatic precipitators (ESPs) for the recovery boiler at the Mörrum pulp mill.

ANDRITZ will replace the discharge electrodes and collecting plates in the ESPs’ first fields and install state-of-the-art high voltage energization units – Switched Integrated Rectifiers (SIR) – in all fields. These latest-generation SIRs, equipped with silicon carbide power electronics, offer the highest electrical efficiency in the market, resulting in considerable energy savings for plant operators. ANDRITZ’s multipeak electrodes will enhance the recovery of residual salts to be recirculated into the process.

This upgrade will be carried out on one ESP at a time and does not require costly and time-consuming field extensions. As a result, downtime of the recovery boiler and impact on the mill’s production will be reduced to a minimum.

www.andritz.com