www.industryemea.com

07

'24

Written on Modified on

Fusion Record Set for Tungsten at WEST Tokamak by U.S. Researchers with Swiss PILATUS X-Ray Detector

DECTRIS is proud to be part of this success, which highlights the key role of public-private partnerships, as well as that of Swiss technology based on Hybrid Photon Counting, in advancing energy research.

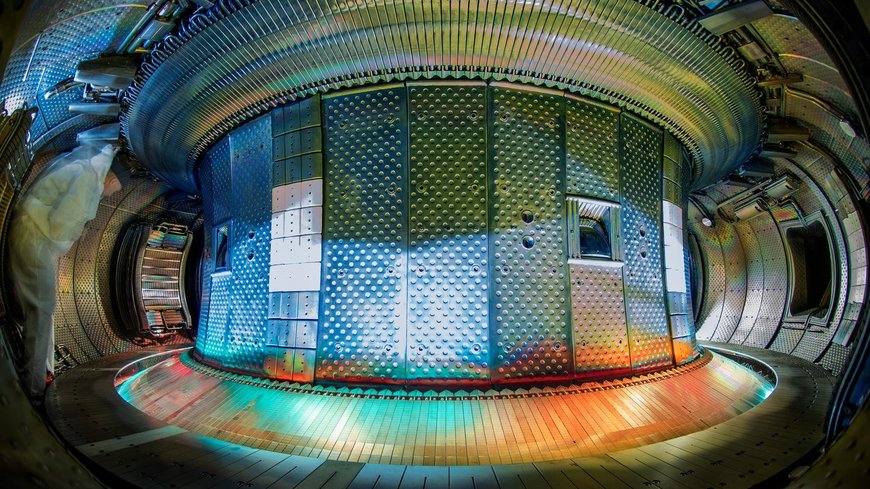

The interior of WEST, the Tungsten Environment in Steady-state Tokamak, where the fusion record was achieved.

Researchers at the Princeton Plasma Physics Laboratory of the U.S. Department of Energy have set a new fusion record using PILATUS3 detectors provided by DECTRIS. The record was set at WEST, the Tungsten Environment in Steady-state Tokamak; the fusion device sustained a hot plasma at about 50 million degrees Celsius for six minutes. DECTRIS is proud to be part of this success, which highlights the key role of public-private partnerships, as well as that of Swiss technology based on Hybrid Photon Counting, in advancing energy research. Finally, the record was made possible thanks to an X-ray detector called “PILATUS3”, which was specifically modified and improved for monitoring super-hot plasma in harsh and challenging conditions.

PPPL’s Tullio Barbui, Novimir Pablant and Luis Delgado-Aparicio work on their multi-energy soft X-ray detector ME-SXR at DECTRIS.

Researchers at the Princeton Plasma Physics Laboratory of the U.S. Department of Energy have set a new fusion record using PILATUS3 detectors provided by DECTRIS. The record was set at WEST, the Tungsten Environment in Steady-state Tokamak; the fusion device sustained a hot plasma at about 50 million degrees Celsius for six minutes. DECTRIS is proud to be part of this success, which highlights the key role of public-private partnerships, as well as that of Swiss technology based on Hybrid Photon Counting, in advancing energy research. Finally, the record was made possible thanks to an X-ray detector called “PILATUS3”, which was specifically modified and improved for monitoring super-hot plasma in harsh and challenging conditions.

PPPL’s Tullio Barbui, Novimir Pablant and Luis Delgado-Aparicio work on their multi-energy soft X-ray detector ME-SXR at DECTRIS.

- A record measurement of long-lasting, super-hot, 50-million-degree plasma was achieved at WEST Tokamak, France by PPPL researchers with PILATUS3 detectors that were specifically designed for the application.

- More than 15 years of public-private partnership between DECTRIS and the PPPL enabled development of the best-adapted X-ray detector for the challenging environment of tokamaks.

- Specific Solutions, such as the PILATUS3 used at WEST, are customized X-ray detectors with specific geometries and physical properties such as magnetic-field tolerance and vacuum compatibility.

- The “thermometer” that was used to measure this record is an X-ray diagnostic tool, developed by the PPPL and enabled by DECTRIS technology.A record measurement of long-lasting, super-hot, 50-million-degree plasma was achieved at WEST Tokamak, France by PPPL researchers with PILATUS3 detectors that were specifically designed for the application.

X-ray detectors play a critical role in nuclear fusion, a process that recreates conditions close to those on the Sun and could satisfy the never-ending need for energy on Earth. To that end, plasma must be contained and kept in a steady state for as long as possible in fusion devices such as tokamaks, machines that confine plasma — the fourth state of matter — in a donut-shaped vessel using magnetic fields. To achieve this, researchers study plasma, control it, and analyze its dynamics to ensure it is stable. As most of the power from a plasma fusion setup is radiated in the form of X-rays, reliable X-ray detectors are needed to monitor the plasma and its processes within the container. Therefore, close collaboration among researchers, fusion facilities, and X-ray detector manufacturers such as DECTRIS is essential to develop the best-adapted tools for this endeavor.

The fusion record set by researchers from the PPPL was achieved because three critical components that are needed to produce energy were brought together. On top of the super-hot temperature of the plasma and the six-minute duration of the experiment, the measurement was made in a tokamak internally clad in tungsten, the element that could be the best fit for the commercial-scale machines that are required to make fusion reactors and produce energy. A previous version of the device — Tore Supra — achieved a slightly longer reaction, but back then, the machine’s interior was made of carbon. While carbon makes the environment easier for long reactions, it may not be suitable for a large-scale reactor because it tends to retain the fuel in the wall. Tungsten is advantageous for retaining far less fuel. However, fusion experiments in tungsten machines are very difficult because, if even minute amounts of tungsten get into the plasma, radiation from them can rapidly cool the plasma. DECTRIS Ltd a pioneer in X-ray detector technology, has partnered since 2007 with the Advanced Projects team of the PPPL to develop detectors that are specifically designed for plasma monitoring. “DECTRIS’ earliest large contract in 2007 was a special configuration of 4 PILATUS 100K cameras for the Princeton Plasma Physics Laboratory”, recalls Christian Brönnimann, DECTRIS’ founder and President of the Board. “The huge success of this project was the basis of our business in plasma fusion diagnostics and our very successful collaboration with the PPPL. We congratulate the PPPL for this outstanding milestone, which will have a big impact on our path towards a sustainable future!” Luis Delgado-Aparicio, PPPL’s Head of Advanced Projects and Lead Scientist for physics research and the X-ray detector project, explains further: “We use the emitted X-rays and their intensity for plasma diagnostics, which allow us to understand how it moves, but also to measure its temperature, velocity, pressure, and density. This is why we depend on reliable X-ray detectors in our work”.

A Long-Lasting partnership

“The plasma fusion community was among the first to test the Hybrid-Photon-Counting technology to monitor plasma dynamics”, says DECTRIS Head of Sales Nicolas Pilet, who has been working with Luis’ team for many years on the joint development of specific detectors, the DECTRIS Specific Solutions. “Today, WEST achieved unprecedented results, and we would like to congratulate the team on their success. Plasma fusion is a fascinating scientific field that holds great promise for humanity. We are incredibly proud to contribute to this development with our products, and are thrilled by our excellent collaboration”. At WEST, PPPL researchers used a novel approach to measure several properties of the plasma radiation. Their approach involved a specially adapted X-ray detector, which was made by DECTRIS and modified by Luis and others on his research team. “The diagnostic basically measures the X-ray radiation produced by the plasma”, says Tullio Barbui, one of the researchers. “Through the measure of this radiation, we can infer very important properties of the plasma, such as the electron temperature in the real core of the plasma, where it is the hottest”.

Specific Detectors for Plasma Diagnostics

DECTRIS Specific Solutions enable usage in a vacuum, in magnetic fields, and in the special geometry that is needed for plasma spectroscopy. DECTRIS provides a specific geometry of the camera to study the X-rays emitted by the plasma. Researchers can “observe X-rays using pinhole cameras” and “scan the whole plasma emission”, as Luis explained during a visit to DECTRIS’ headquarters in 2019. “The X-ray detector involved in measuring several properties of the plasma radiation is exposed to the harsh environment of the tokamak”, explains Benjamin Lüthi, Project Lead for Specific Solutions at DECTRIS. “In a fruitful collaboration between PPPL researchers and DECTRIS engineers over many years, this custom-made detector was continuously improved towards a highly reliable and well-performing X-ray camera”.

Benjamin also highlights the importance of testing at tokamaks in product development: “We extensively test components under a vacuum and in strong magnetic fields. But, most importantly, we continuously integrate the feedback and results received from the tests performed at tokamaks, and this enables us to further develop the next-generation detector”.The tungsten environment is very relevant to future fusion reactors to produce energy, and contributed to our common success. A previous version of the device — Tore Supra — achieved a slightly longer reaction, or shot, but back then, the machine’s interior was made of graphite tiles.

While carbon makes the environment easier for long shots, it may not be suitable for a large-scale reactor because the carbon tends to retain the fuel in the wall, which will be unacceptable in a reactor where efficient recovery of tritium from the reactor chamber and reintroduction into the plasma will be paramount. Tungsten is advantageous for retaining far less fuel, but if even minute amounts of tungsten get into the plasma, radiation from the tungsten can rapidly cool the plasma.“The tungsten-wall environment is far more challenging than using carbon,” said Delgado-Aparicio. “This is, simply, the difference between trying to grab your kitten at home versus trying to pet the wildest lion.”Our main assets at DECTRIS are our proximity to the scientific community and our intimate relationships with researchers around the world. Thanks to this mutual trust, we can help them solve important challenges and achieve great results with our detectors. DECTRIS is proud to be part of this story and excited to continue working with researchers to make fusion a sustainable source of energy for mankind.

www.dectris.com

The fusion record set by researchers from the PPPL was achieved because three critical components that are needed to produce energy were brought together. On top of the super-hot temperature of the plasma and the six-minute duration of the experiment, the measurement was made in a tokamak internally clad in tungsten, the element that could be the best fit for the commercial-scale machines that are required to make fusion reactors and produce energy. A previous version of the device — Tore Supra — achieved a slightly longer reaction, but back then, the machine’s interior was made of carbon. While carbon makes the environment easier for long reactions, it may not be suitable for a large-scale reactor because it tends to retain the fuel in the wall. Tungsten is advantageous for retaining far less fuel. However, fusion experiments in tungsten machines are very difficult because, if even minute amounts of tungsten get into the plasma, radiation from them can rapidly cool the plasma. DECTRIS Ltd a pioneer in X-ray detector technology, has partnered since 2007 with the Advanced Projects team of the PPPL to develop detectors that are specifically designed for plasma monitoring. “DECTRIS’ earliest large contract in 2007 was a special configuration of 4 PILATUS 100K cameras for the Princeton Plasma Physics Laboratory”, recalls Christian Brönnimann, DECTRIS’ founder and President of the Board. “The huge success of this project was the basis of our business in plasma fusion diagnostics and our very successful collaboration with the PPPL. We congratulate the PPPL for this outstanding milestone, which will have a big impact on our path towards a sustainable future!” Luis Delgado-Aparicio, PPPL’s Head of Advanced Projects and Lead Scientist for physics research and the X-ray detector project, explains further: “We use the emitted X-rays and their intensity for plasma diagnostics, which allow us to understand how it moves, but also to measure its temperature, velocity, pressure, and density. This is why we depend on reliable X-ray detectors in our work”.

A Long-Lasting partnership

“The plasma fusion community was among the first to test the Hybrid-Photon-Counting technology to monitor plasma dynamics”, says DECTRIS Head of Sales Nicolas Pilet, who has been working with Luis’ team for many years on the joint development of specific detectors, the DECTRIS Specific Solutions. “Today, WEST achieved unprecedented results, and we would like to congratulate the team on their success. Plasma fusion is a fascinating scientific field that holds great promise for humanity. We are incredibly proud to contribute to this development with our products, and are thrilled by our excellent collaboration”. At WEST, PPPL researchers used a novel approach to measure several properties of the plasma radiation. Their approach involved a specially adapted X-ray detector, which was made by DECTRIS and modified by Luis and others on his research team. “The diagnostic basically measures the X-ray radiation produced by the plasma”, says Tullio Barbui, one of the researchers. “Through the measure of this radiation, we can infer very important properties of the plasma, such as the electron temperature in the real core of the plasma, where it is the hottest”.

Specific Detectors for Plasma Diagnostics

DECTRIS Specific Solutions enable usage in a vacuum, in magnetic fields, and in the special geometry that is needed for plasma spectroscopy. DECTRIS provides a specific geometry of the camera to study the X-rays emitted by the plasma. Researchers can “observe X-rays using pinhole cameras” and “scan the whole plasma emission”, as Luis explained during a visit to DECTRIS’ headquarters in 2019. “The X-ray detector involved in measuring several properties of the plasma radiation is exposed to the harsh environment of the tokamak”, explains Benjamin Lüthi, Project Lead for Specific Solutions at DECTRIS. “In a fruitful collaboration between PPPL researchers and DECTRIS engineers over many years, this custom-made detector was continuously improved towards a highly reliable and well-performing X-ray camera”.

Benjamin also highlights the importance of testing at tokamaks in product development: “We extensively test components under a vacuum and in strong magnetic fields. But, most importantly, we continuously integrate the feedback and results received from the tests performed at tokamaks, and this enables us to further develop the next-generation detector”.The tungsten environment is very relevant to future fusion reactors to produce energy, and contributed to our common success. A previous version of the device — Tore Supra — achieved a slightly longer reaction, or shot, but back then, the machine’s interior was made of graphite tiles.

While carbon makes the environment easier for long shots, it may not be suitable for a large-scale reactor because the carbon tends to retain the fuel in the wall, which will be unacceptable in a reactor where efficient recovery of tritium from the reactor chamber and reintroduction into the plasma will be paramount. Tungsten is advantageous for retaining far less fuel, but if even minute amounts of tungsten get into the plasma, radiation from the tungsten can rapidly cool the plasma.“The tungsten-wall environment is far more challenging than using carbon,” said Delgado-Aparicio. “This is, simply, the difference between trying to grab your kitten at home versus trying to pet the wildest lion.”Our main assets at DECTRIS are our proximity to the scientific community and our intimate relationships with researchers around the world. Thanks to this mutual trust, we can help them solve important challenges and achieve great results with our detectors. DECTRIS is proud to be part of this story and excited to continue working with researchers to make fusion a sustainable source of energy for mankind.

www.dectris.com