www.industryemea.com

05

'24

Written on Modified on

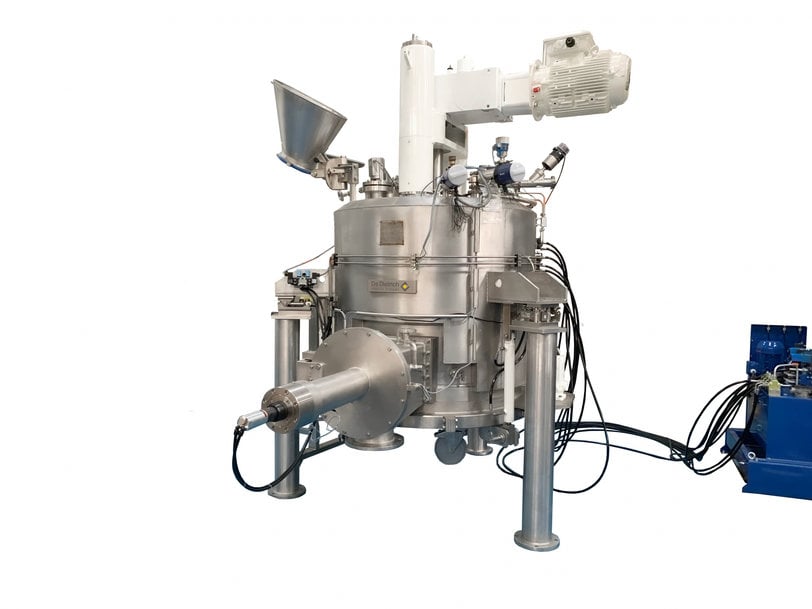

A New Standard in Vegetal Extraction: The Filtering Bottom Extractor from De Dietrich Process Systems

Thanks to the expertise of De Dietrich Process Systems, the Agitated Filtering Bottom Extractor has become the benchmark for the vegetal extraction and green chemistry industries.

www.dedietrich.com

A Major Advancement in Vegetal Extraction

De Dietrich Process Systems introduces an innovation in solid-liquid extraction with its Filtering Bottom Extractor. This equipment maximizes extraction efficiency and is an undeniable asset for the vegetal extraction and green chemistry industries. Its innovative design allows for faster and more complete extraction of valuable molecules, thereby reducing production costs and increasing the profitability of extraction processes.

Unmatched Versatility

The Agitated Filtering Bottom Extractor stands out for its ability to perform several critical extraction process steps in a single device. It not only allows the extraction of valuable molecules but also the desolvatation through vacuum drying of the residues, potentially valorized as by-products, and achieving a yield up to six times higher than conventional static extractors.

The equipment is available in a wide range of sizes, from 105 liters to 5,000 liters. Options for control, loading, unloading, and cleaning cater to each user's needs for simplified operation. Whether for branches, twigs, chips, or powders, this extractor offers unparalleled robustness and ease of use.

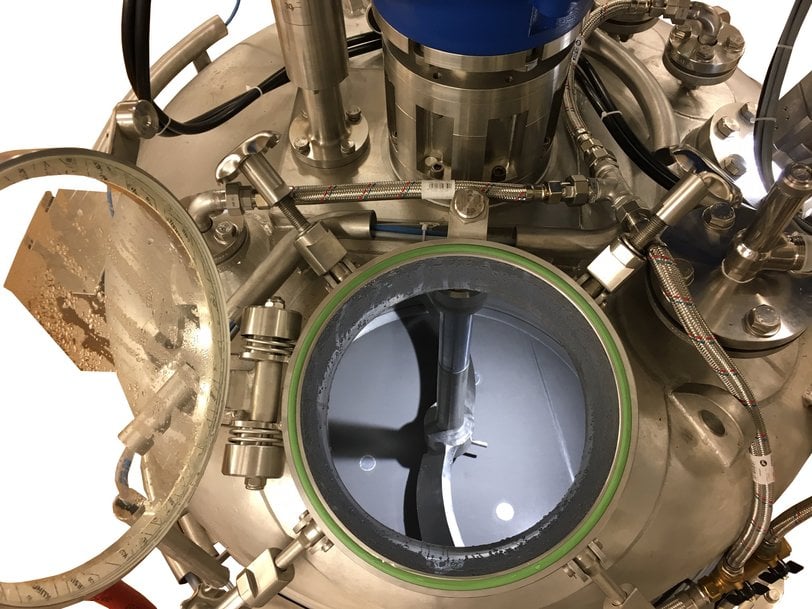

The Pilot Unit: A New Standard for Process Development

To support the development of extraction processes, De Dietrich also offers a pilot unit of the filtering bottom extractor. This stainless steel 316L equipment is a standard version with optimized cost. Supplied directly with solvent condenser and TCU, this pilot is easily transportable and installable. This pilot has proven effective in numerous R&D projects, including cold extractions down to -25°C, a growing trend in the sector.

With a capacity of 20 liters, the equipment includes a standard tilting bottom for easy waste removal and cleaning, as well as an optimized condensation system.

The De Dietrich Tech Lab: An Innovation Platform

For clients looking to test and optimize their processes, the De Dietrich Tech Lab in Semur-en-Auxois offers an ideal environment. The Tech Lab provides pilot solid-liquid extractors for tests that can be carried out on-site or at the Tech Lab under expert supervision. This laboratory offers a wide range of configurations to help clients validate and develop their own processes: process characterization, efficiency improvement, and equipment scale-up. The Tech Lab ensures safety and compliance for process testing with its ATEX-compatible room.

Comprehensive Engineering Solutions for Your Extraction Needs

De Dietrich Process Systems does not only supply extraction equipment. With the PGS Pharma & Green Solutions engineering teams, the group's expertise also extends to providing the entire production line, from extraction to the final product, including loading. The group regularly complements extraction with molecular distillation solutions, a sought-after expertise for the purification of extracts. These systems are crucial for separating and valorizing thermosensitive valuable compounds.

A Promising Future for Vegetal Extraction

The bottom filter extractor from De Dietrich Process Systems represents a significant advancement for the vegetal extraction and green chemistry industries. Its innovative design, efficiency, and profitability make it an essential choice. Combined with the Tech Lab's infrastructure and PGS engineering services, this equipment opens up limitless possibilities for optimizing extraction processes.

www.dedietrich.com

www.dedietrich.com