www.industryemea.com

02

'17

Written on Modified on

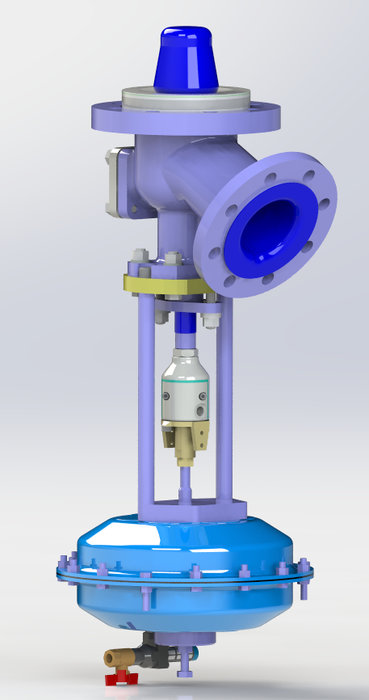

De Dietrich Process Systems permanently adapts its disc bottom outlet valve to customer’s needs

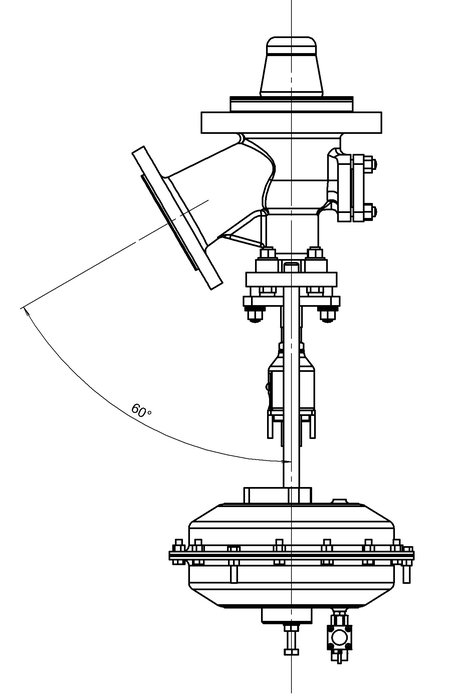

To allow an easy interchangeability and compatibility to its customers in pharmaceutical and fine chemical field, DDPS has extended its range of disc bottom outlet valves by adding a 60° outlet nozzle version.

This DIN Norm defines the angle (60°) as well as the exact position of the outlet nozzle flange.

This allows easy retrofitting on existing reactors and tanks made of glass-lined steel, stainless steel or nickel alloy.

All features of Cleanvalve 45° are preserved with all its advantages and benefits.

MAIN ADVANTAGES

Cleanvalve has been designed with the most rigorous cleaning operations in mind:

• Patented flat seat to avoid collection or build-up of materials in the annular area between the valve seat and nozzle wall

• Self draining design of the internal components and body

• Cleanvalve is able to accommodate temperature measurement sensors, measurement electrodes at the lowest point in the vessel for a more accurate and reliable temperature measurement

• Lateral dismantling of the temperature probe

• All De Dietrich Process Systems glass-lined valves are made of cast steel coated with the standard DD3009 enamel identical to the reactors on which they are installed. Wetted parts feature the same characteristics of all other glass-lined equipment including resistance to corrosion, thermal and mechanical shock

MAIN BENEFITS

• Draining design, elimination of dead space, easy to clean to avoid cross contamination

• No need to dismantle the valve between batches, reduces production costs

• Safe and reliable

For any further information (price, delivery time…), please contact:

De Dietrich Process Systems

30 Grand Rue

67110 Zinswiller

France

Phone: +33 3 88 53 23 00

This email address is being protected from spambots. You need JavaScript enabled to view it.

www.dedietrich.com